Welding Habitat System

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

In the context of performing hot work within hot work habitats, ensuring safe work practices is paramount. Areas designated for special hot work without graded controls are potentially explosive atmospheres that could lead to disasters at any moment. To mitigate the risks associated with cutting and welding operations in hazardous environments such as the world’s numerous offshore drilling platforms and areas with dangerous gases, Eleclifeoem has developed a welding habitat system specifically designed for potentially explosive atmospheres, ensuring the safety of personnel, the environment, and equipment.

Over the past 20 years, Eleclifeoem’s welding habitat system has saved global enterprises upwards of 30 billion USD, servicing more than 130 companies. This achievement underscores the critical role that advanced safety systems play in maintaining operational integrity and preventing catastrophic incidents in high-risk areas.

– Welding Habitat System –

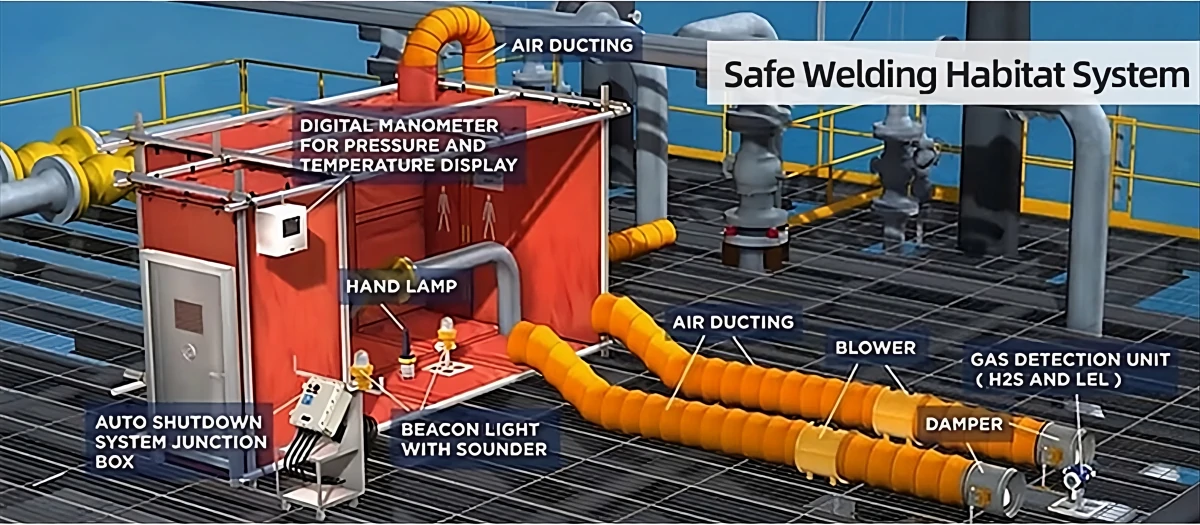

Within the working environment, the system’s flexible flameproof panels contain sparks and slag leaks within the work area. The pressure differential module pressurizes the welding habitat to prevent dangerous gases such as LPG and hydrogen from entering.

The gas detection module monitors the presence of hazardous gases like LPG and hydrogen. Upon detection, it transmits data to the central controller system. This central system then controls the welding module, halting operations to ensure safety.

The welding habitat system acts as a seamless barrier, providing multiple layers of protection that ensure maximum construction safety. This comprehensive approach not only mitigates risks but also enhances the overall security and efficiency of operations in hazardous environments.

| Model | Basic Fabric | Coating |

| HKWS-3732 | 3732 E-Glass Fiberglass Fabric | Silicone |

| HKWS-H300 | 300G High Silica Fabric | Silicone |

| HKWS-H600 | 600G High Silica Fabric | Silicone |

|

Certification

|

ATEX,UL,FM4950

|

|||

|

Introduction

|

Safe Welded Habitat Panels are made of high performance fiberglass cloth coated with grey/orange silicone. Can be used for pipeline insulation, fire protection and temperature protection in the oil exploration industry.

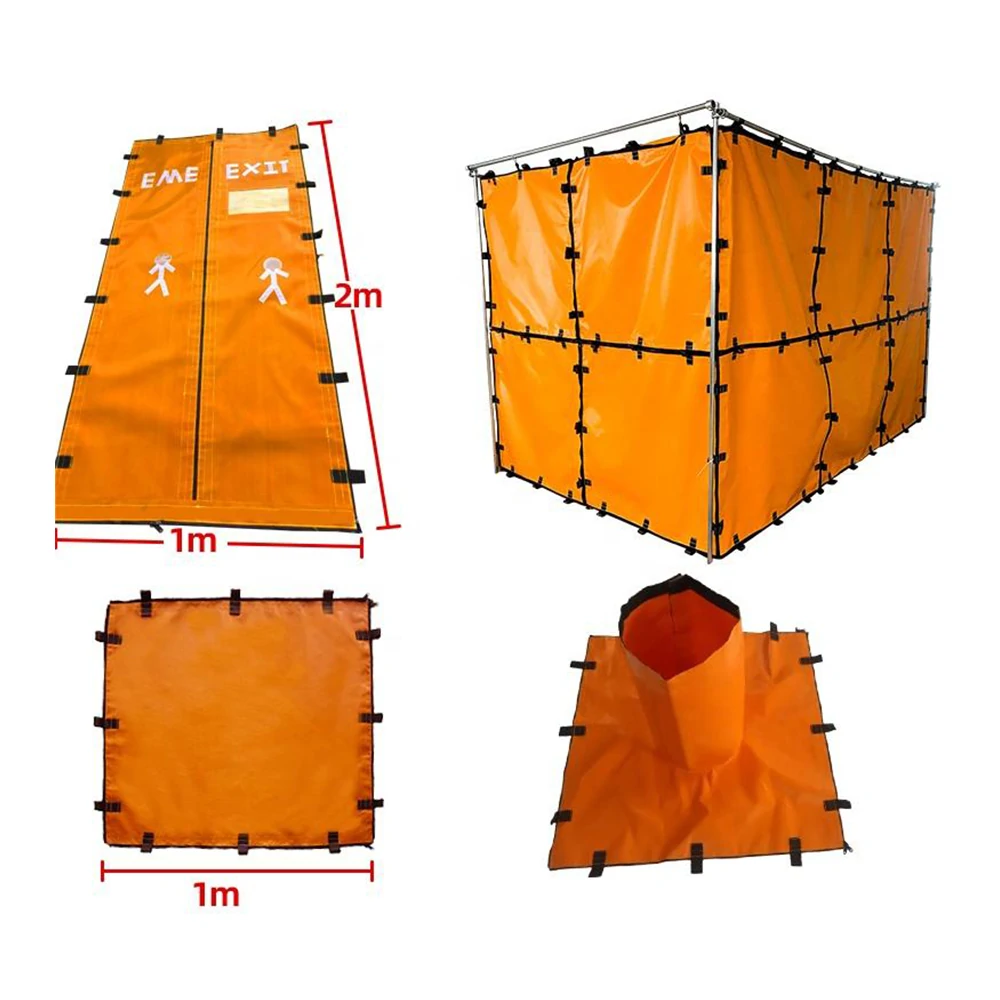

Specifications: panel standard size 1m*1m, 2m*1m, 2m*2m Panels are made of lightweight flame retardant fiberglass material Accessories: flame retardant zipper,flame retardant hook and loop tape, eye pad, tape, etc |

|||

|

Advantage

|

1. 100% made of fiberglass cloth with temperature resistance of 800℃.

2. High temperature resistant fireproof thread (K e v l a r) sewing. 3. Black customized fire resistant zippers. 4. Black customized fire resistant drawstrings. 5. Black customized fire resistant Velcro. |

|||

– Welding Habitat System Parts –

Welding Habitat:

Eleclifeoem’s welding habitat is crafted from silicone-coated fiberglass fabric or silicone-coated high silica fabric, interconnected through fire-resistant panel interlocks to ensure both fire resistance and seal integrity. These materials are capable of withstanding long-term operating temperatures of up to 1000°C (1832°F), providing robust protection against extreme heat conditions typical in hazardous work environments. This design ensures that the habitat remains a secure and controlled space, effectively shielding both workers and equipment from fire-related risks.

Pressure Differential Module

The Pressure Differential Module (PDM) is installed within the pressurized welding habitat. The Habitat PDM is designed to monitor the internal pressure levels and will issue alerts to the users if the pressure drops below safe thresholds. This system plays a crucial role in maintaining a controlled environment, ensuring that the habitat’s integrity is uncompromised and that hazardous gases are kept at bay, thereby safeguarding both personnel and operations within the habitat.

Gas Detection Module

The Gas Detection Module is tasked with monitoring the ambient air within the habitat to ensure it remains safe for inhalation. This module is particularly critical as it cuts off airflow if it detects the presence of hydrocarbons or hydrogen sulfide. By doing so, it prevents these hazardous gases from compromising the air quality inside the habitat, thus significantly enhancing the safety and viability of operations within potentially dangerous environments. This module is a vital component of the overall safety management system, ensuring that environmental conditions within the welding habitat are continuously monitored and maintained within safe parameters.

Remote Gas Sensor

The Remote Gas Sensor is designed to measure air quality outside the welding habitat. This sensor is critical for preemptive safety measures, as it immediately shuts down equipment if it detects hazardous gases in the surrounding environment. This capability not only prevents the ingress of dangerous gases into the habitat but also ensures that any potential risks are mitigated before they can impact the safety of the operations and personnel inside the habitat. This proactive approach is essential for maintaining a high level of safety in environments where volatile or toxic gases may be present.

Welding Control Module (WCM)

The Welding Control Module (WCM) is a sophisticated component of the welding habitat system that ensures compliance by automatically shutting down electrical or pneumatic tools after their use. This feature is crucial for maintaining strict safety standards within the habitat, as it helps prevent any accidental fires or explosions that could arise from improper tool management. The WCM’s automated control not only enhances safety but also boosts operational efficiency by ensuring that all tools are used and managed according to strict protocols, reducing the risk of human error and increasing the overall reliability of the welding operations.

– Welding Habitat System Advantage –

Control of Sparks: The habitat is equipped with fire-resistant materials and advanced spark containment systems that capture and neutralize sparks from hot work. This prevents any errant sparks from coming into contact with flammable gases outside the habitat.

Use of Internal Overpressure: The habitat maintains a slight overpressure internally to prevent the ingress of any flammable gases. This positive pressure barrier ensures that the interior of the habitat is isolated from potentially hazardous external atmospheres.

Isolation of the Welding Area: The welding area within the habitat is specifically designed to contain the heat source and all associated risks. This isolation is achieved through the use of fire-resistant panels and tightly sealed access points, ensuring that the heat and any dangerous by-products are confined within a controlled space.

Positive Barrier Creation: A critical safety feature is the establishment of a positive barrier between the welding operations and any nearby flammable materials. This is achieved through both physical and pressure barriers, effectively separating and shielding the two.

Limitation of Dangerous Sparks and Spatters: The habitat’s design incorporates materials and technologies that limit the escape of dangerous sparks and spatters during welding operations. These include specialized coatings and structures within the habitat that capture or neutralize these potential hazards before they can pose a risk.

– Welding Habitat System Application –

- Marine and Offshore Industry: These systems are indispensable for repairing and maintaining ships and offshore platforms. In marine environments, welding often must be performed under conditions of high humidity and salinity, which can challenge traditional welding setups. The welding habitat system offers a dry, wind-free environment, mitigating contamination and fire risks during welding processes.

- Oil and Gas Industry: When welding on oil drilling platforms and in refineries, fire and explosion prevention are paramount. Welding habitats isolate workers from potentially flammable gases and vapors, ensuring a safer welding operation. This isolation is critical in environments where the presence of hydrocarbons increases the risk of fire and explosions.

- Chemical Plants: Chemical manufacturing often requires welding repairs on pipelines and equipment. These environments may contain flammable or hazardous chemicals. A welding habitat system provides a controlled environment that minimizes the interference from external factors, thus reducing the risk of incidents related to the exposure of volatile or toxic substances.

- Construction and Infrastructure Building: In the construction of bridges, high-rise buildings, and other critical infrastructures, welding habitat systems protect the welding area from adverse weather conditions and also safeguard the workers from environmental hazards. This protection is essential in ensuring that structural integrity is maintained and that construction timelines are met without safety compromises.

- Emergency Repairs and Rapid Response Operations: Welding habitats are especially valuable in emergency repair situations requiring quick responses. These systems can be rapidly deployed to provide a secure environment for welding, which is crucial in minimizing downtime and restoring functionality to critical infrastructure or equipment swiftly.

Related products

-

Vermiculite Coated High Silica Fiberglass Fabric

Heat Resistant Fabric -

PVC Coated Fiberglass Fabric

Heat Resistant Fabric -

PTFE Mesh

Heat Resistant Fabric -

Tear & Crease Resistant Teflon Coated Glass Fabric

Heat Resistant Fabric