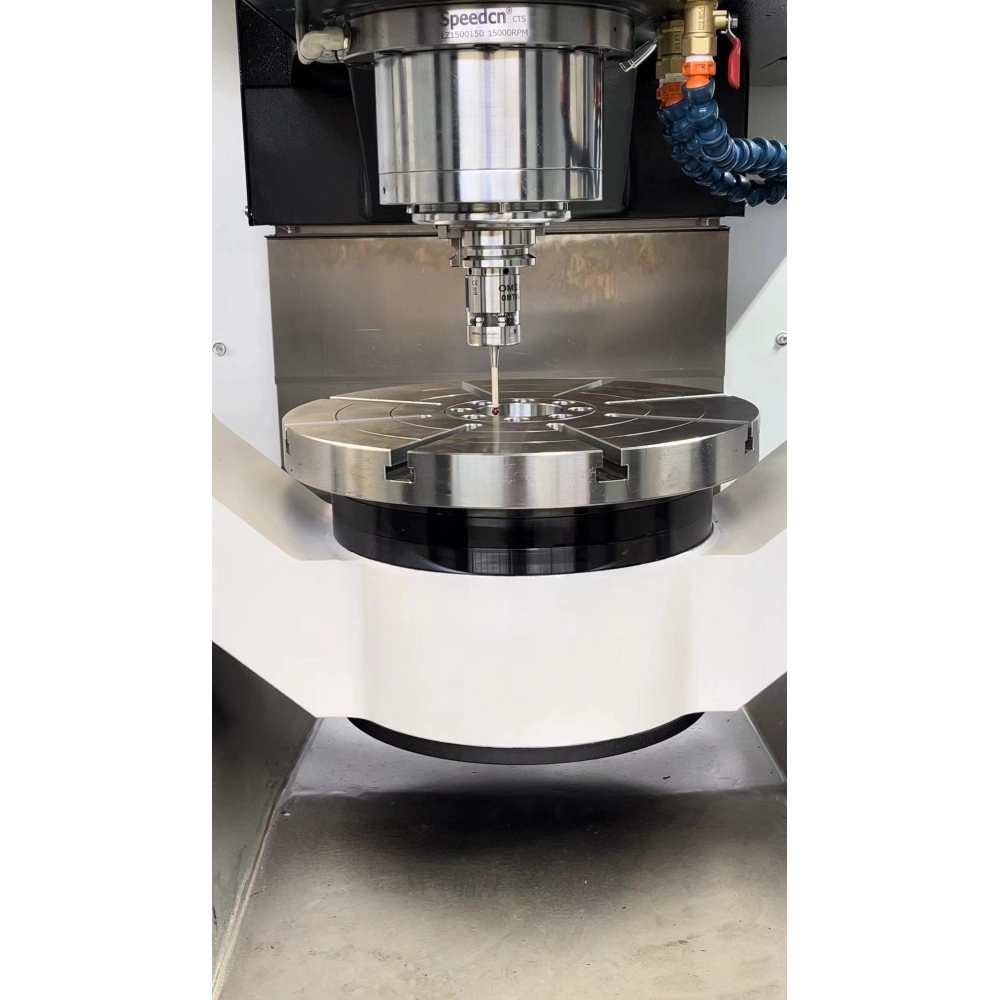

Vertical 5-axis CNC Metal Milling Machine Center For Complex Surface Machining

0

+ Pieces sold in the past 30 days

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

|

project

|

designation

|

parameters

|

remarks

|

|

processing range

|

Distance from spindle nose to disk surface(mm)

|

45-645

|

Disk level

|

|

Table Travel

|

X-axis Stroke(mm)

|

800

|

X-axis

|

|

Y-axis Stroke(mm)

|

550

|

Y-axial

|

|

|

Vertical stroke(mm)

|

600

|

Z-axis

|

|

|

Cradle

|

drive mode |

Moment motor direct drive

|

|

|

The A-axis swing angle(deg)

|

±130 °

|

Sloping shaft

|

|

|

The C-axis swing angle(deg)

|

n×360 °

|

rotation axis

|

|

|

Disk diameter(mm)

|

Φ350

|

||

|

Maximum workpiece diameter(mm)

|

Φ500

|

||

|

T groove(n/mm)

|

4/12H7

|

||

|

Maximum height of artifacts(mm)

|

340

|

||

|

Workpiece load capacity(kg)

|

≤50

|

||

|

A-axis torque (rated / max. N.m)

|

120/240

|

DD Straight drive

|

|

|

C axis torque(Rated / max. N.m)

|

45/135

|

DD Straight drive

|

|

|

principal axis |

Taper hole model

|

BBT40

|

|

|

maximum speed(rpm)

|

12000

|

||

|

driving mode

|

Direct connection

|

||

|

power rating(kW)

|

7.5/11

|

||

|

rating torque(N.m)

|

32

|

S1

|

|

|

numerical control system

|

System brand

|

LYNUK N5E

|

|

|

Operate the screen

|

A 15-inch color screen

|

||

|

drive |

X/Y/Z ball screw(Diameter guide mm)

|

4012

|

|

|

X/Y/Z Axis guide rail

|

45#/45#/45#

|

||

|

X/Y/Z Fast moving speed(m/min)

|

30/30/30

|

Motor at 3,000 rpm

|

|

|

A / C axis fast speed(m/min)

|

100/200

|

||

|

X/Y/Z power of motor (kW)

|

2.9/2.9/4.4

|

Z axis lock

|

|

|

tool magazine |

Knife library capacity (handle)

|

24

|

|

|

Change change time (knife to sec)

|

2

|

||

|

Maximum tool length (mm)

|

250

|

||

|

Maximum tool weight(kg)

|

8

|

||

|

Maximum knife plate adjacent knife diameter(mm)

|

70/120

|

||

|

Machine tool accuracy |

X/Y/Z positioning accuracy(mm)

|

0.005

|

|

|

X/Y/Z Repeat positioning accuracy(mm)

|

0.003

|

||

|

A/C positioning accuracy(sec)

|

±8

|

||

|

A/C Repeat positioning accuracy(sec)

|

±6

|

||

|

Machine tool size

|

Machine tool size

|

About 2550 * 2400 * 2550

|

Long * wide * high

|

|

Machine tool weight(t)

|

About 6

|

||

|

other

|

numerical control system

|

LYNUK N5E

|

|

|

Total electrical capacity Kw

|

20

|

||

|

Pressure required MPa

|

0.6~0.7

|

||

|

The gas flow required(m³/min)

|

0.15

|

||

|

power requirement

|

Three-phase at 380V / 50Hz

|

requirements and other auxiliary equipment

|

serial number

|

project

|

requirement

|

|

1

|

ambient temperature

|

Working environment temperature + 5℃ ~ + 40℃. After the ambient temperature, air conditioning should be added to ensure processing

accuracy |

|

2

|

ambient humidity

|

Relative humidity of 80%

|

|

3

|

Lightning protection

|

Equipment installation environment should be lightning protection measures, if there is no lightning protection measures, in the

lightning weather, possible Can cause a lightning strike accident |

|

4

|

surrounding environment

|

1. The machine tool should not be installed within the range of direct sun; 2. Stay away from oil pollution, dust and corrosive

gas; 3. Stay away from the equipment with large vibration, such as air compressor room, punch workshop, etc.; 4. A distance of at least 1m apart from any other equipment (or wall); 5. Stay away from electrical interference equipment, such as electric welding machine, etc. |

|

5

|

Installation of the ground requirements

|

The ground should be stable and strong, and the height difference should not be more than within the effective installation range

of any single machine tool 10mm。 |

Related products

-

Hot Sale Machining Horizontal Sumore 5 Axis Price CNC Milling Machine Center

Horizontal Milling Machine -

Milling Machineremote Monitorin Plc Horizontal Boring Machine Content Boring-Milling Machine

Horizontal Milling Machine -

Milling Machine VM-949-1

Milling Machine