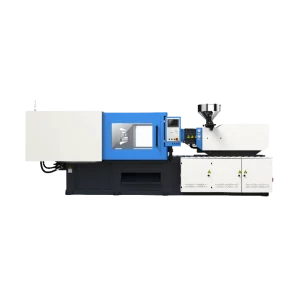

Toggle Hydraulic Injection Molding Machine(90T-650T)

The Series Toggle Hydraulic Injection Molding Machine adopts advanced oil circuit design and is equipped with a professional controller, which enables stable machine movement, high product yield, and fast response speed. At the same time, the oblique row double injection cylinder and linear guide rail are used to make the glue injection more accurate and stable. The screw is made of high-performance nitrided steel, which is durable and efficient, and has wider applications.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Case & Application

Characteristics

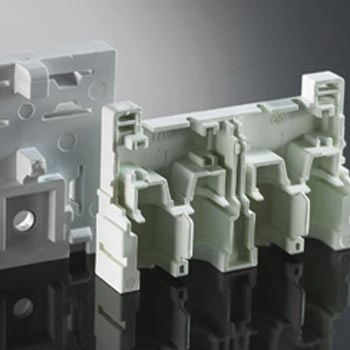

- 1. Strengthening the template enhances its resilience, resulting in a 0.2mm/m template deformation. The rigidity ensures product accuracy, particularly in high-speed and high-pressure working conditions.

- 2. Enhanced power, a maximum injection speed of 145mm/s, and an injection pressure of 290MPa, surpassing the standard machine by over 30%.

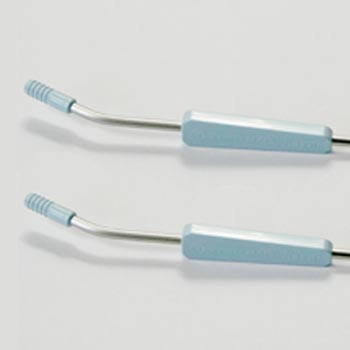

- 3. Premium-quality screw assembly components are designed to accommodate the high-speed and high-pressure requirements of PC and TPU shell parts.

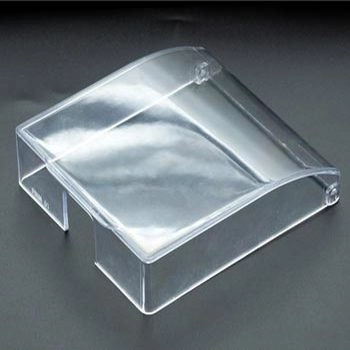

- 4. Utilize ceramic heating elements and implement temperature control at the material inlet, enhancing temperature precision and sensitivity to boost yield.

- 5. Tightly integrated with auxiliary systems and using KEBA controller to ensure convenient and efficient operation.

Application Industries

- Electronics, 3C Home Appliances, Auto Parts, Containers, Cosmetics, Daily Products

The robustness of the series toggle-type hydraulic injection molding machine (90T-650T) is truly impressive. Its outstanding strength during injection molding operations is achieved through careful design, optimized connectors, advanced guide rails and slides, and the incorporation of effective structural anti-vibration measures. This results in the production of precise and high-quality injection molded parts, enhancing the reliability of your production line. With a 30% increase in power, the machine can handle a broader range of tasks. Whether a straightforward injection molding project or a complex production process, the overall power configuration ensures the equipment operates efficiently and steadily, delivering top-notch injection molding products and improving overall production efficiency.

With meticulous processing and assembly, the series toggle hydraulic injection molding machine ensures outstanding stability and reliability in its operation. The utilization of premium-grade screw assemblies allows the equipment to excel under demanding high-pressure and high-load working conditions. Additionally, it features ceramic heating elements, feed inlet temperature control, and seamlessly integrated auxiliary systems, enhancing the overall stability and efficiency of the entire series during the injection molding process. This leads to improved product quality and increased production efficiency.

Related products

-

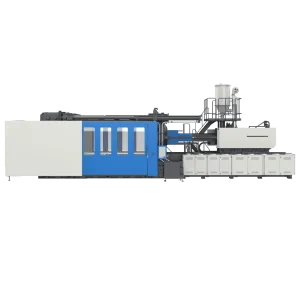

Servo Motor Injection Molding Machine(90Ton-4000Ton)

Injection Molding Machine -

PET Series Injection Molding Machine(170T-470T)

Injection Molding Machine -

Direct Press Type Injection Molding Machine(130T-2800T)

Injection Molding Machine -

All Electric Injection Molding Machine(90T-460T)

Injection Molding Machine