Machine Centre Cnc Vertical Machining Center High Quality Cnc Milling Machining Center

0

+ Pieces sold in the past 30 days

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Machine Centre Cnc Vertical Machining Center High Quality Cnc Milling Machining Center

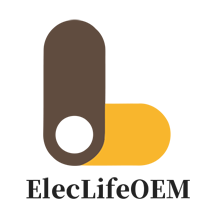

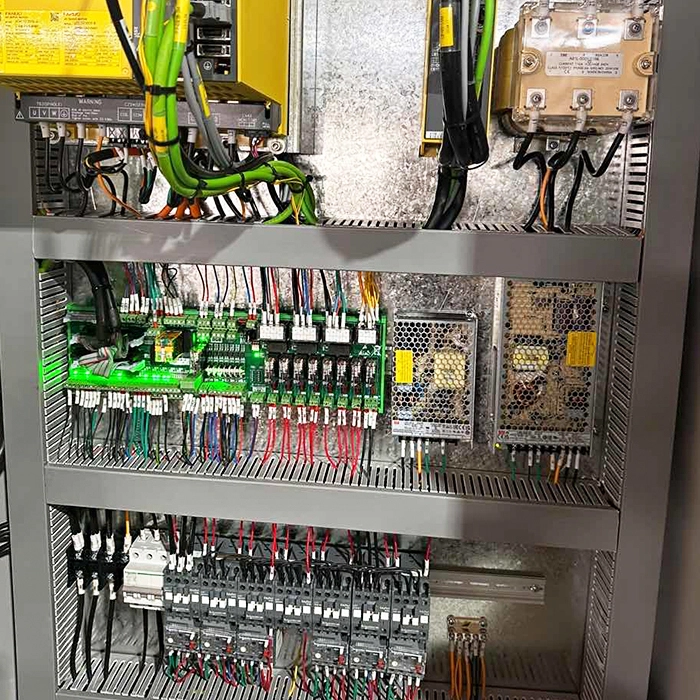

VMC600 machine tool inherits the advantages of strong rigidity, symmetrical structure, and strong stability of the traditional vertical CNC milling machine, and introduces international advanced dynamic rigid design concepts to optimize the design of moving parts. The machine tool has large torque and good quick response characteristics, which is suitable for the needs of various machining fields such as automobiles, molds, aerospace, military, and hardware.

Cnc Machining Center

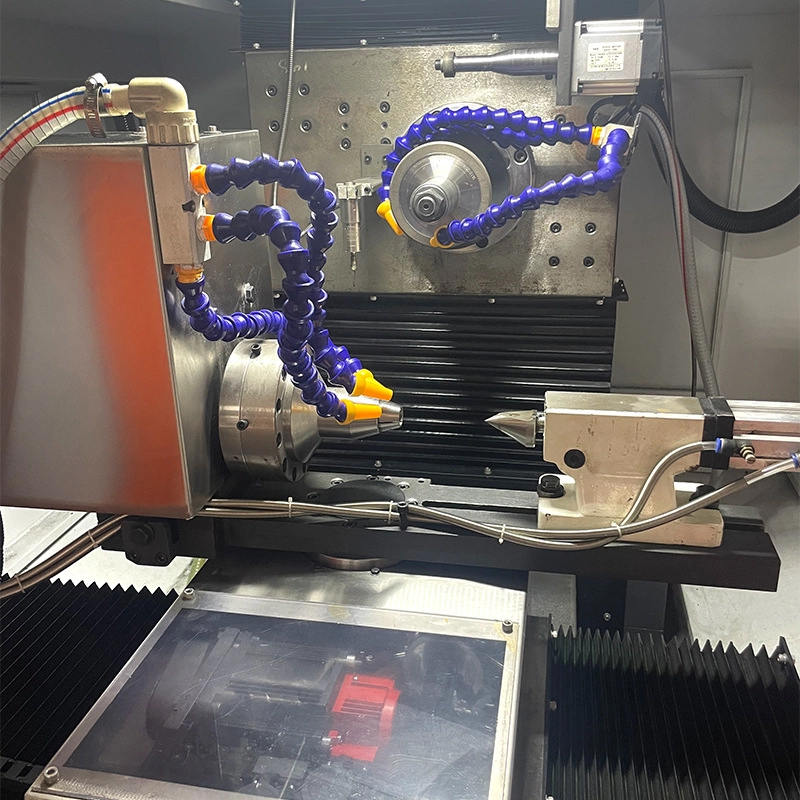

CNC machining center is a CNC machine tool with a tool magazine that can automatically change tools and can perform various processing operations on the workpiece within a certain range. The characteristics of machining parts on the machining center are: after the machined part is clamped once, the CNC system can control the machine tool to automatically select and replace the tool according to different procedures; automatically change the machine tool spindle speed, feed and the movement path of the tool relative to the workpiece And other auxiliary functions, it can continuously and automatically perform multi-process processing such as drilling, countersinking, reaming, boring, tapping, and milling on each processing surface of the workpiece. Since the machining center can complete various processes in a centralized and automatic manner, it avoids human operation errors, reduces workpiece clamping, measurement and adjustment time of machine tools, and workpiece turnover, handling and storage time, greatly improving processing efficiency and machining accuracy. , so it has good economic benefits.

|

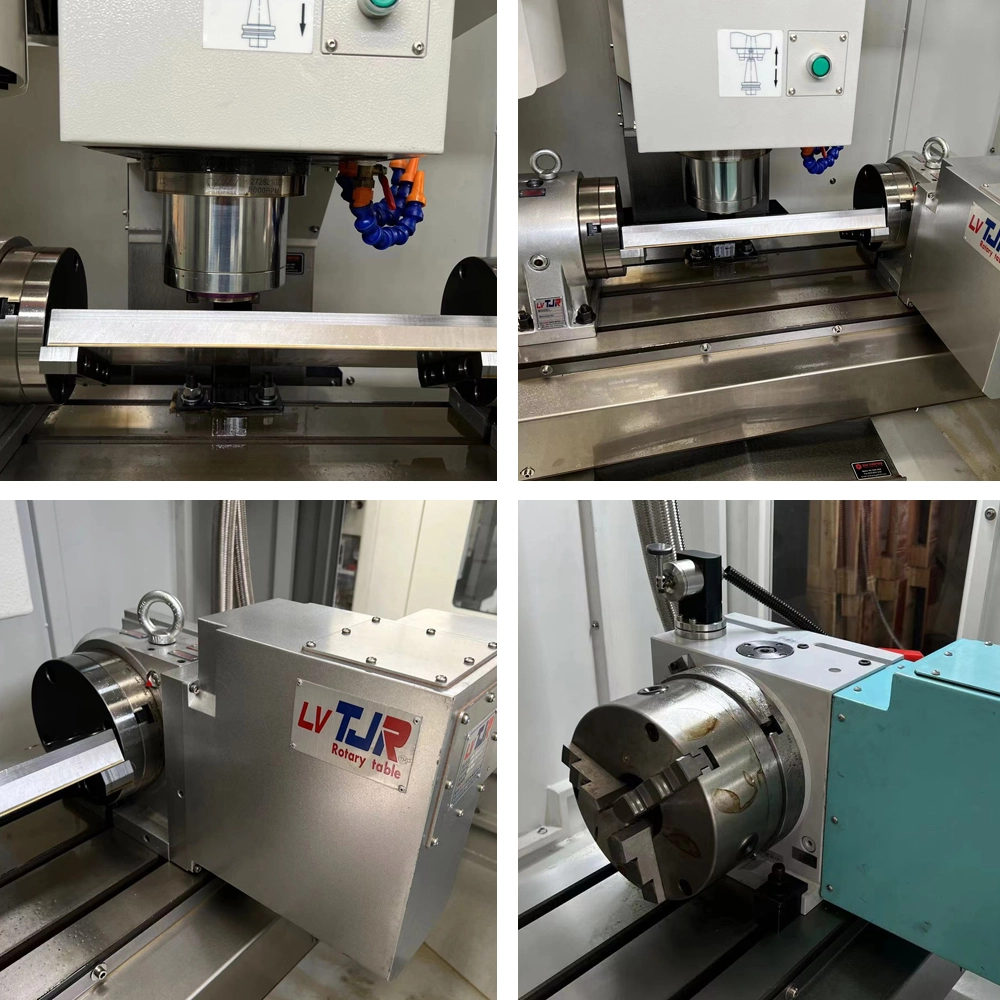

Model

|

VMC 600

|

VMC640

|

VMC650

|

|

Travel parameters of 3 axis

|

|||

|

X /Y/Zaxis travel

|

500/320/450mm

|

600/400/450mm

|

650/450/500mm

|

|

Spindle face to table distance

|

70-520mm

|

80-530mm

|

100-600mm

|

|

Distance between spindle center and column guide surface

|

360mm

|

400mm

|

500mm

|

|

Worktable parameters

|

|||

|

Worktable size

|

800×260mm

|

800×320mm

|

900×400mm

|

|

Maximum load bearing of worktable

|

400kg

|

400kg

|

450kg

|

|

T Shot

|

3×16×75mm

|

3×16×100mm

|

5×16×75mm

|

|

Feeding parameters

|

|||

|

X/Y/Z axis rapid movement rate

|

24/24/16 m/min

|

24/24/16 m/min

|

24/24/16 m/min

|

|

Feed moving velocity X, Y, Z

|

1-10m/min

|

1-10m/min

|

1-10m/min

|

|

Spindle parameters

|

|||

|

Main shaft connection

|

Belt

|

Belt

|

Belt

|

|

Spindle taper

|

BT40-120

|

BT40-120

|

BT40-120

|

|

Range of spindle speed

|

8000rpm

|

8000rpm

|

8000rpm

|

|

Spindle motor power

|

5.5kW(Alternating current servo)

|

5.5KW (Alternating current servo)

|

5.5kW(Alternating current servo)

|

|

ATC paremeters

|

|||

|

ATC capacity

|

12qty

|

16qty

|

16qty

|

|

Maximum tool size

|

Φ92mm(tool from a distance)

|

Φ92mm(tool from a distance)

|

Φ92mm(tool from a distance)

|

|

Maximum tool weight

|

5kg

|

5kg

|

5kg

|

|

Precision

|

|||

|

PositionaI accuracy(JIS standard)

|

±0.008/300mm

|

±0.008/300mm

|

±0.008/300mm

|

|

Repeated positioning accuracy(JIS standard)

|

±0.005mm

|

±0.005mm

|

±0.005mm

|

|

Shape and weight

|

|||

|

Machine size

|

2200×2100×2260mm

|

2600×1950×2400mm

|

2500×2100×2360mm

|

|

Weight

|

2400kg

|

2600kg

|

3800kg

|

Related products

-

High Quality Large Vertical 4 Axis VMC Machine Bt 50 Cnc Big Machining Center

CNC Milling Machine