Low Cost Zero Backlash SHF Harmonic Drive Nema 24 in Sale

1. Rated Power(1):0.1kw~45kw

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product descriptions from the supplier

Overview

Product Description

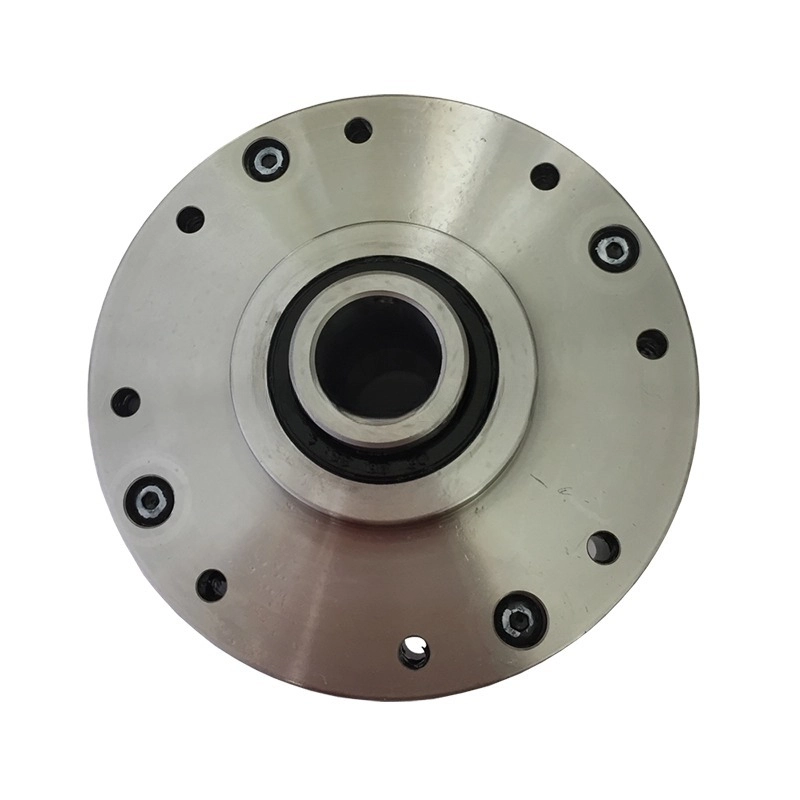

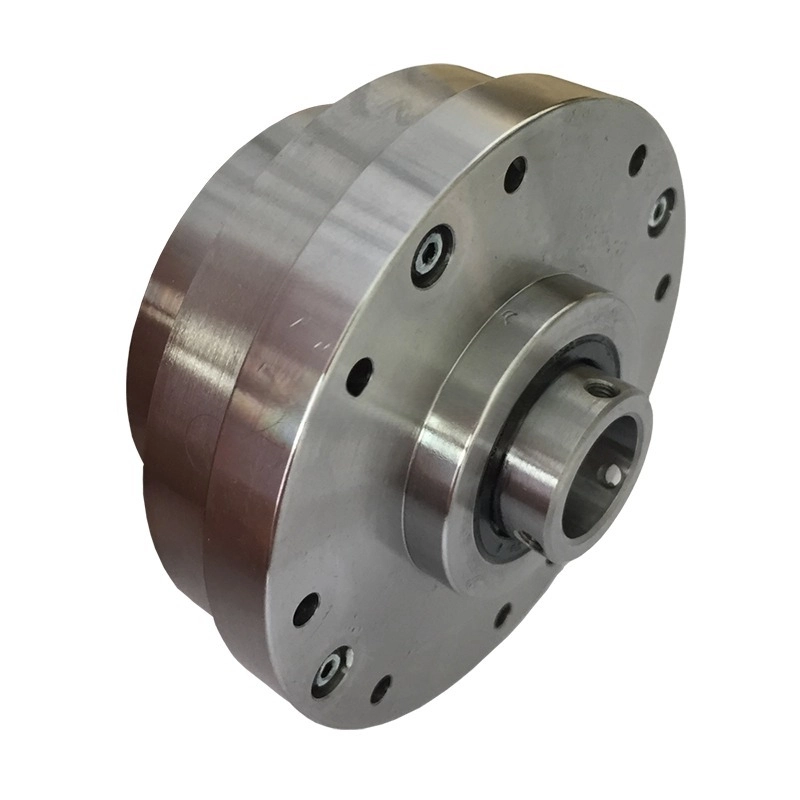

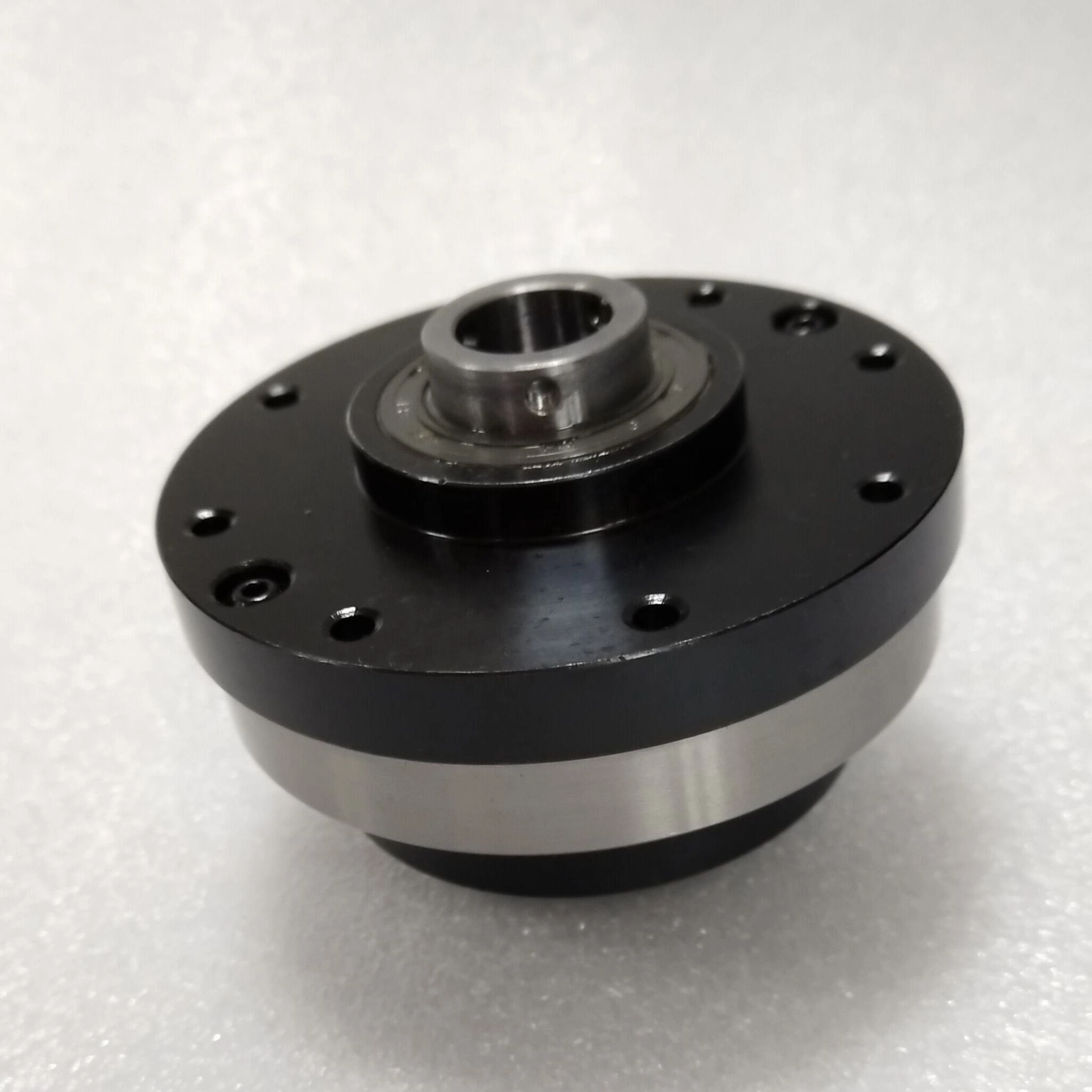

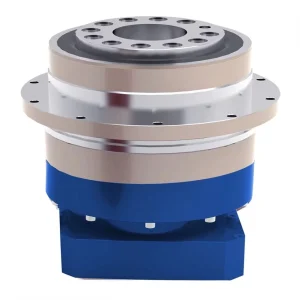

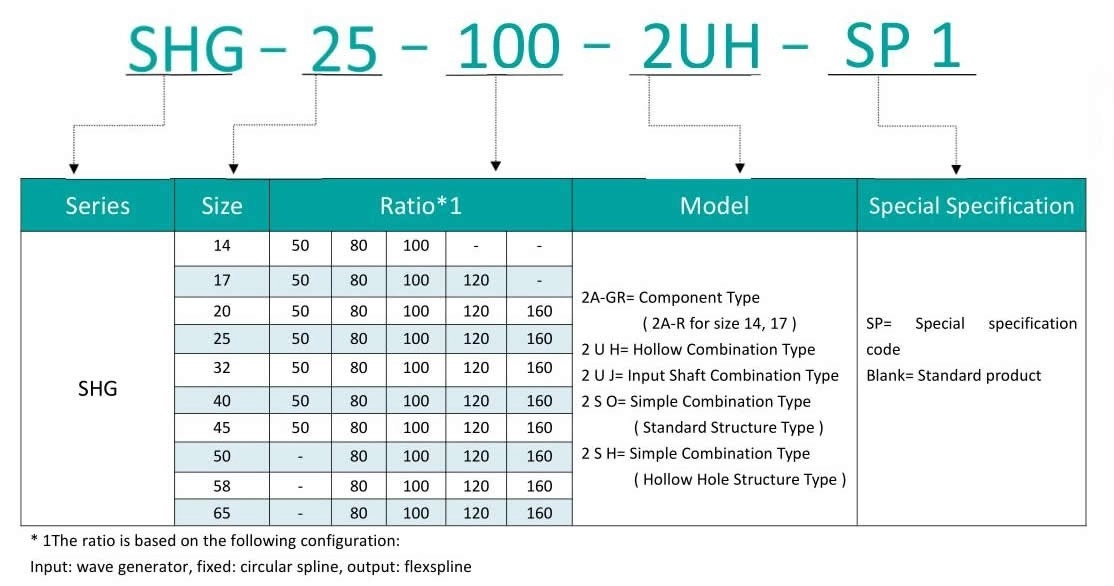

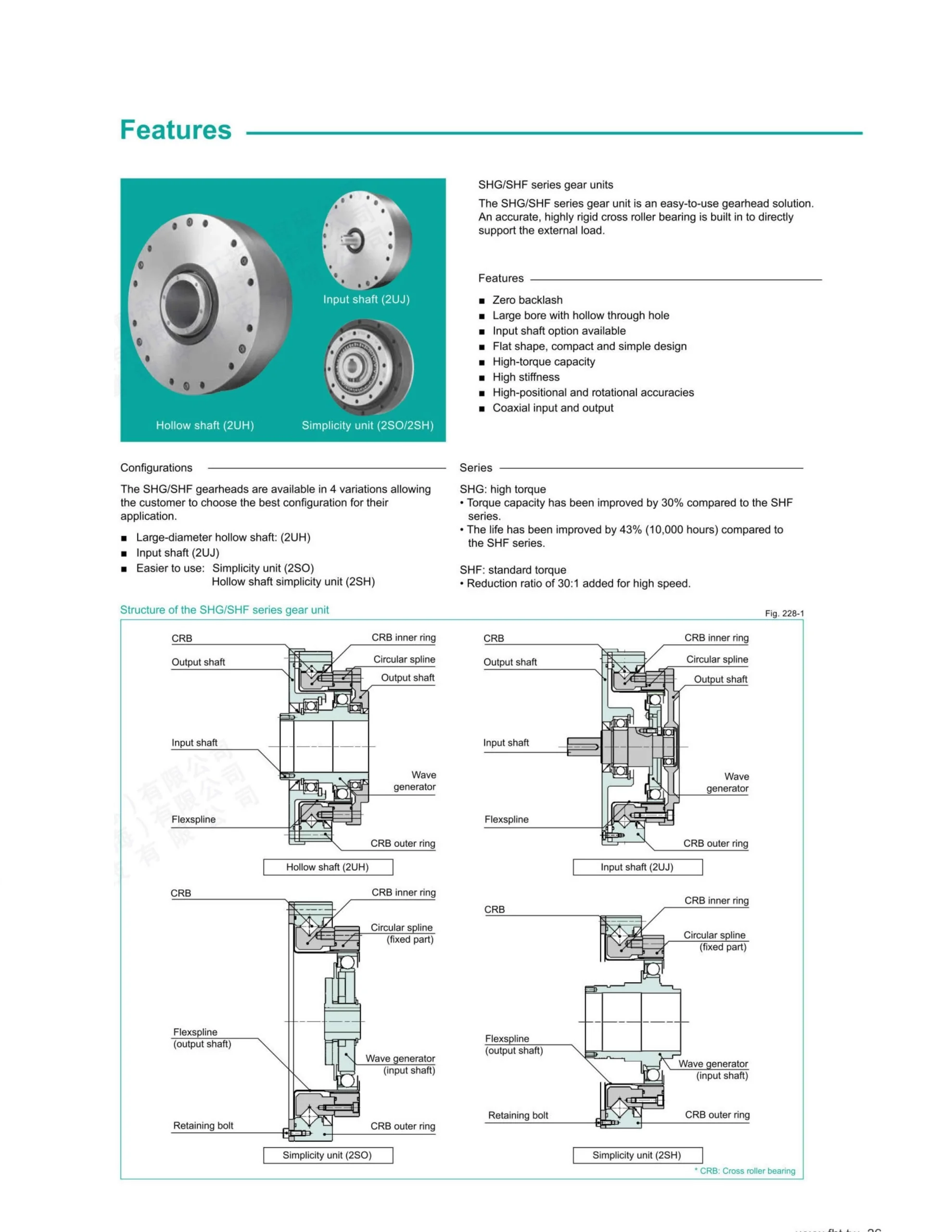

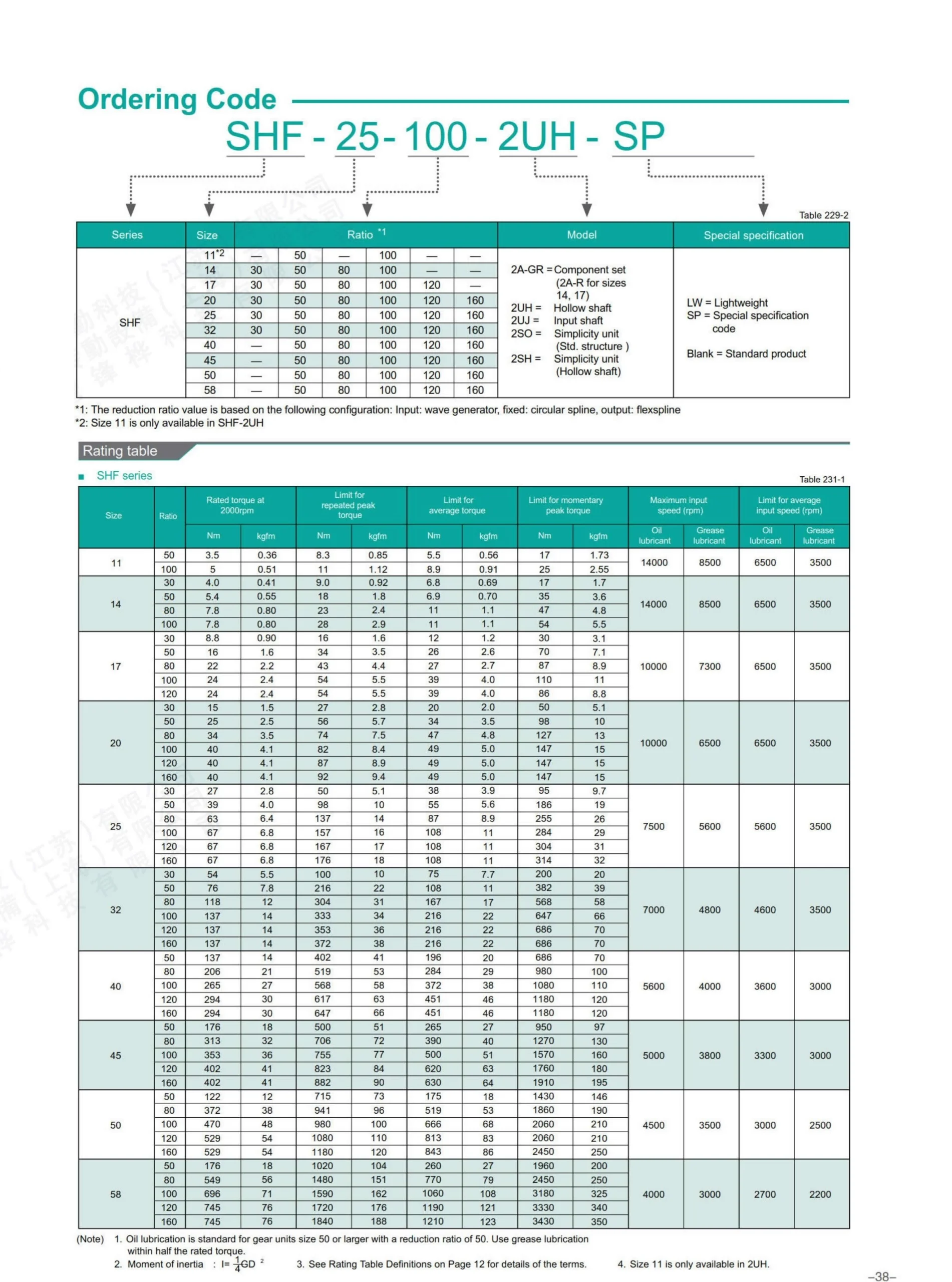

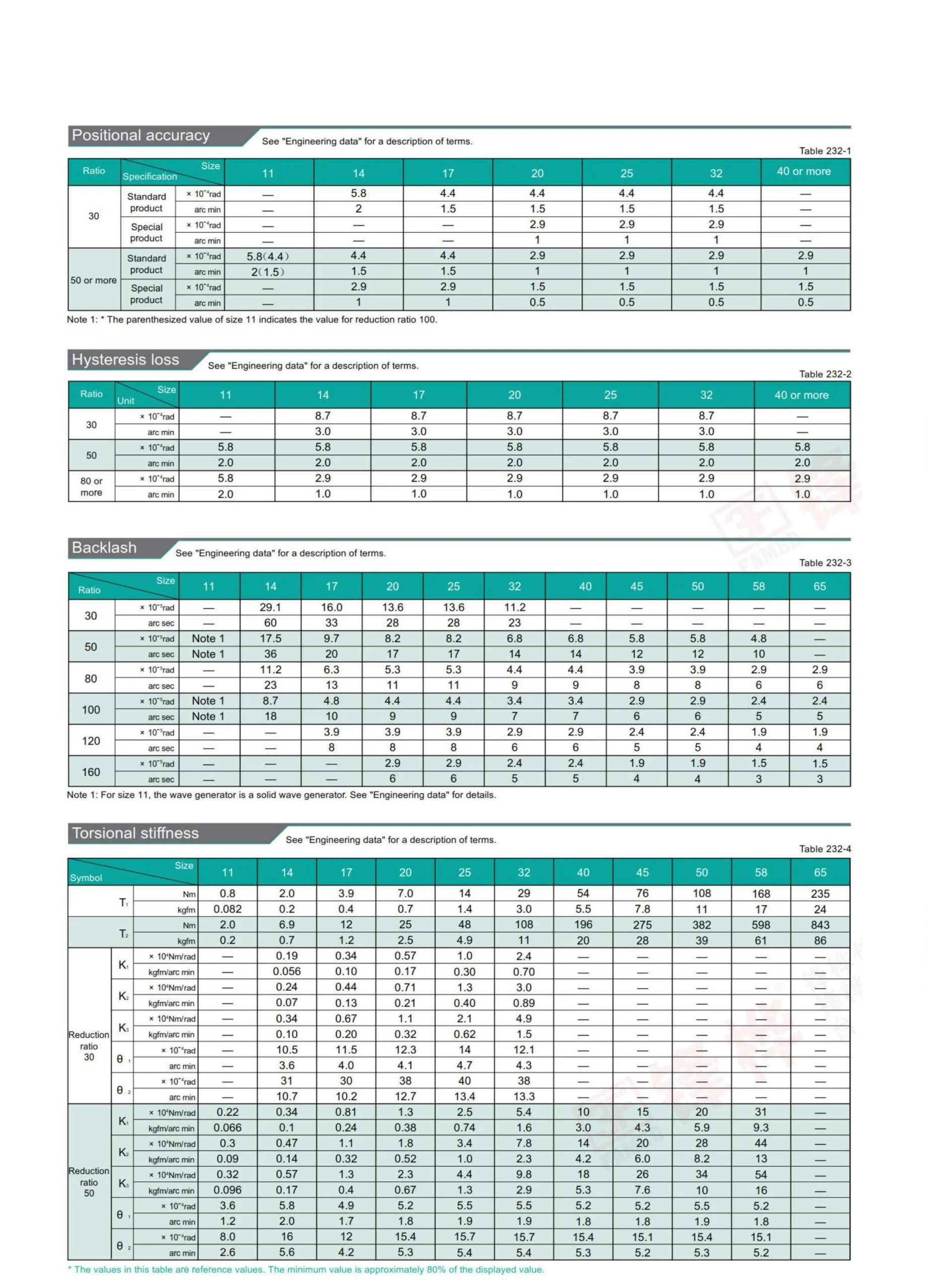

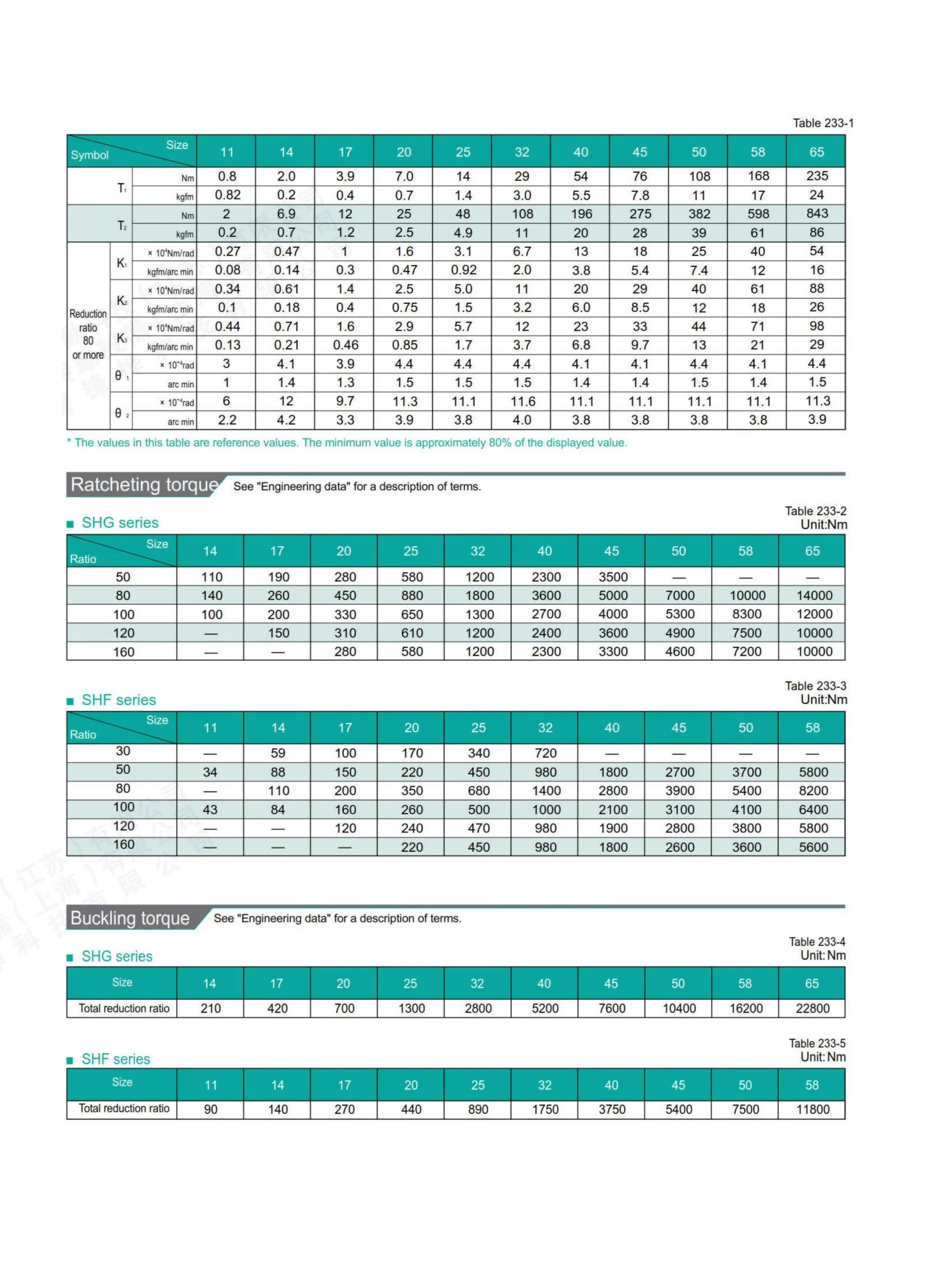

DESCRIPTION OF SHG/SHF SERIES HARMONIC REDUCER

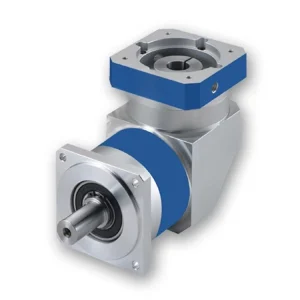

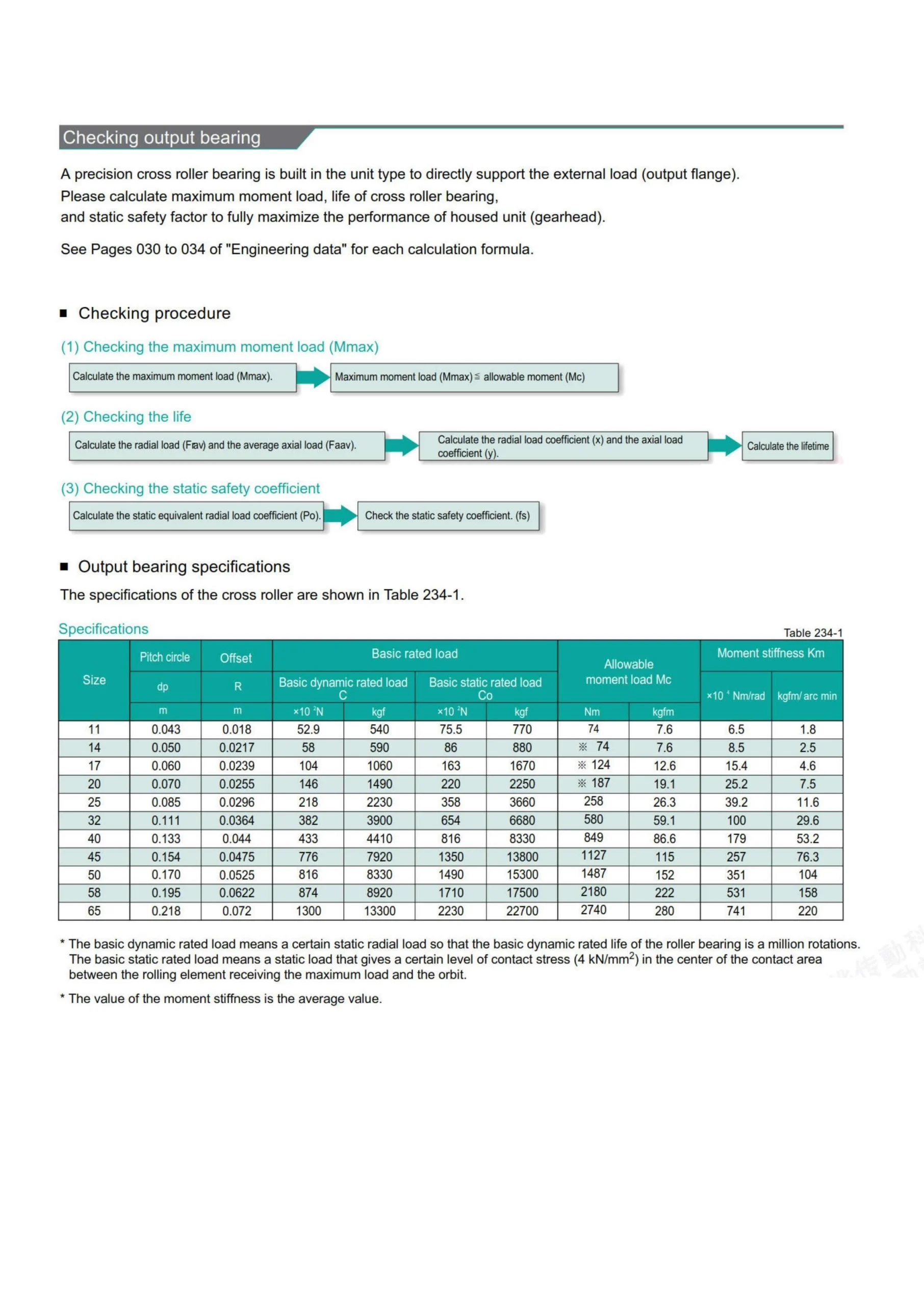

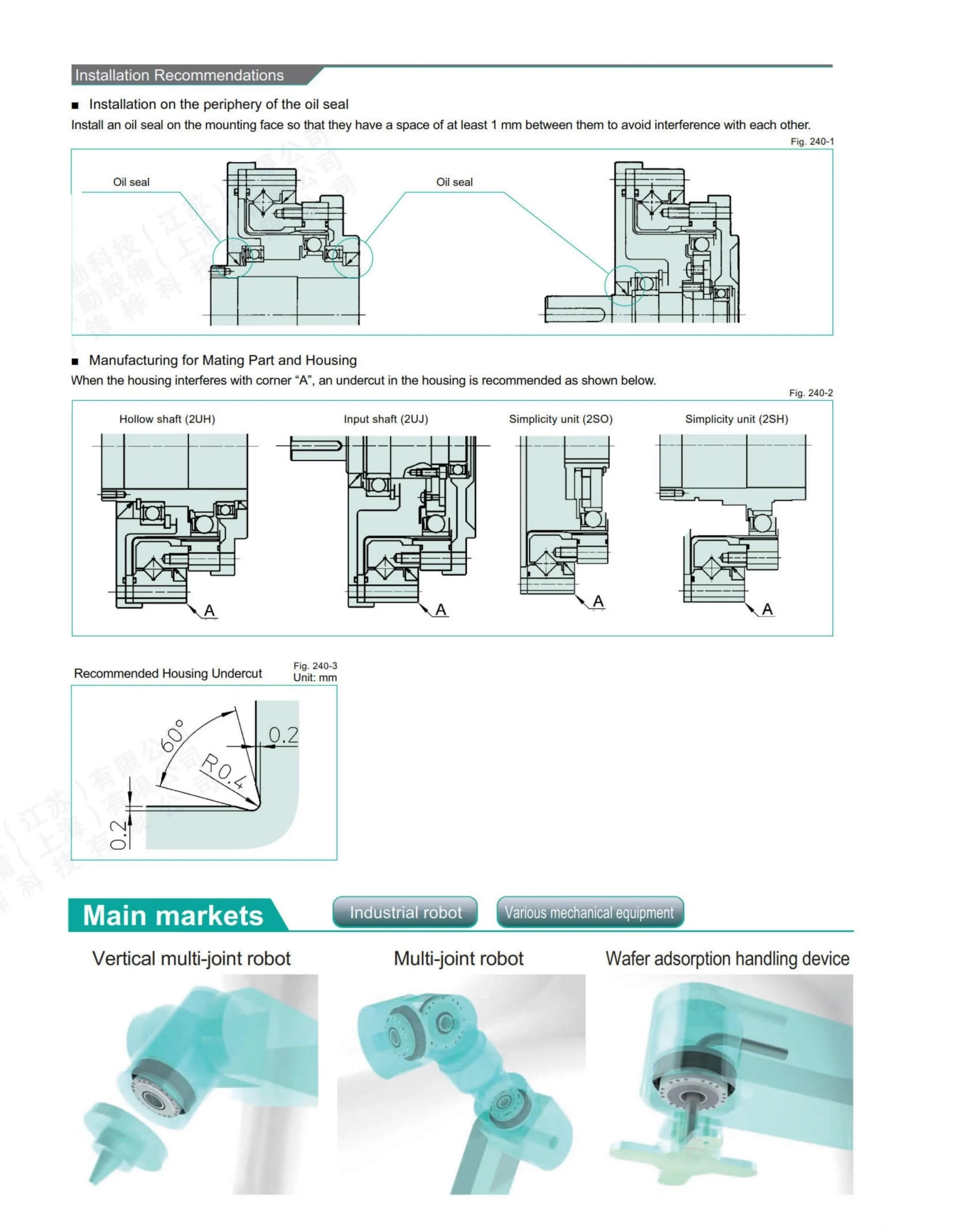

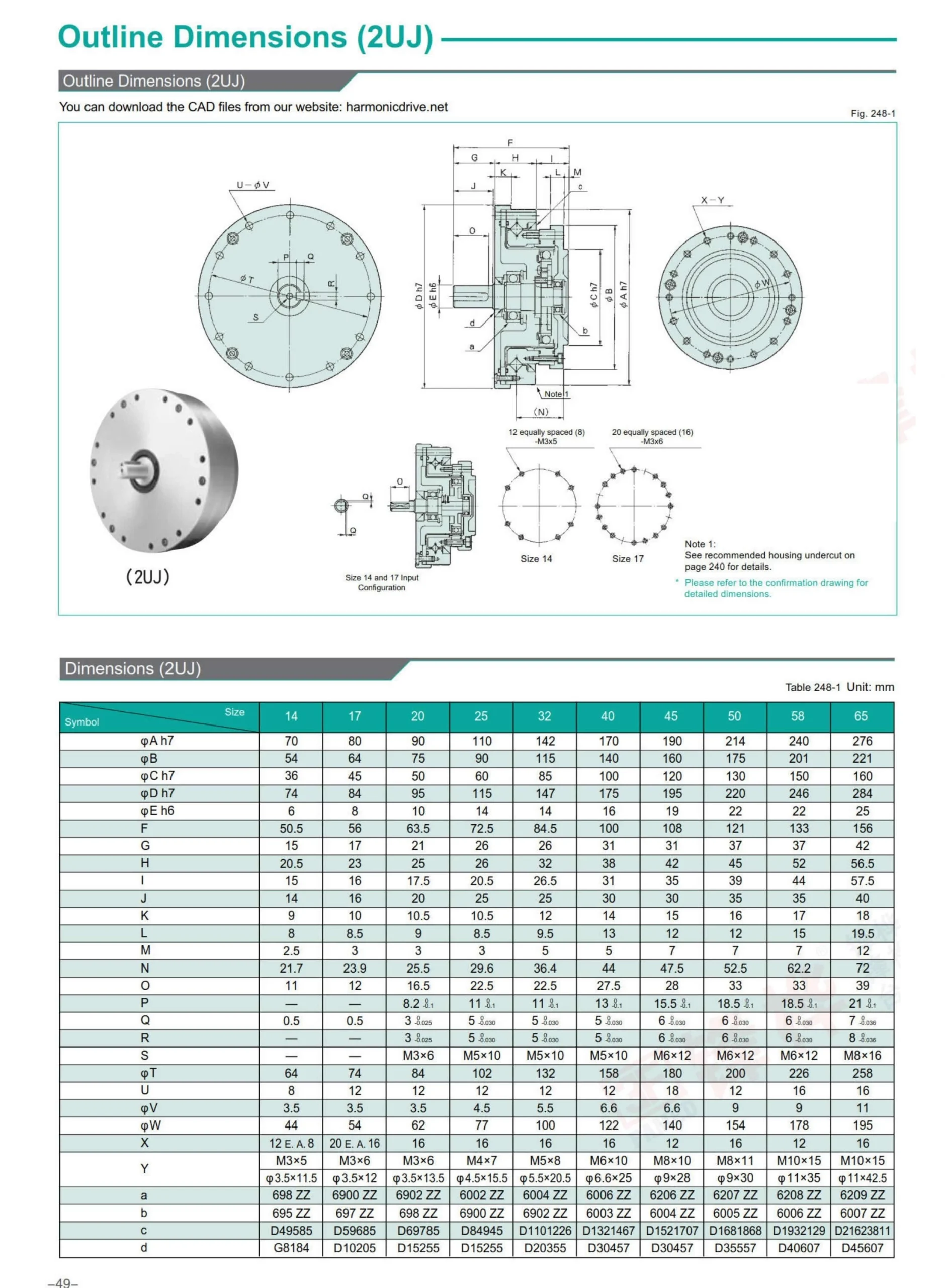

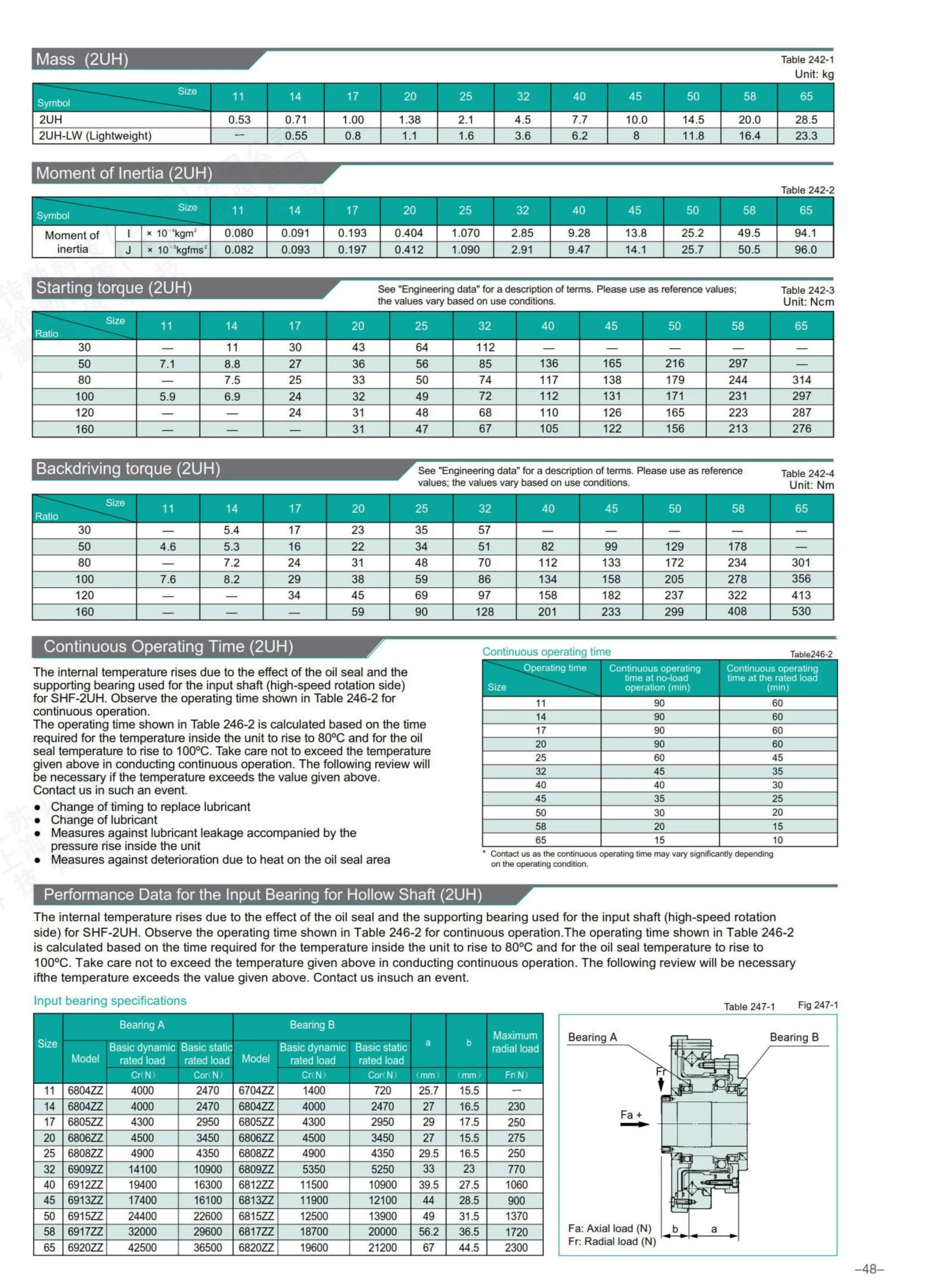

The SHG/SHF series harmonic drive is a component-based product with easy operation. It consists of three basic components wave generator, flexspline and circular spline. SHG/ SHF series harmonic gears are featured of a large hollow input shaft and the cross roller bearings with high rigidity is built for direct support (main bearing) external loads. It adopts the large bore with hollow through hole structure design, and the whole shape of harmonic reducer is flat. The SHG/SHF gearheads are available in 4 variations allowing the customer to choose the best configuration for their application, hollow shaft(2UH), input shaft(2UJ), simplicity unit(2SO) and hollow shaft

OVERVIEW OF SHF SERIES HARMONIC GEAR REDUCER

* Compact and simple design

* High torque capacity

* High stiffness

* Zero backlash

* High-positional and rotational accuracy

* Coaxial input and output

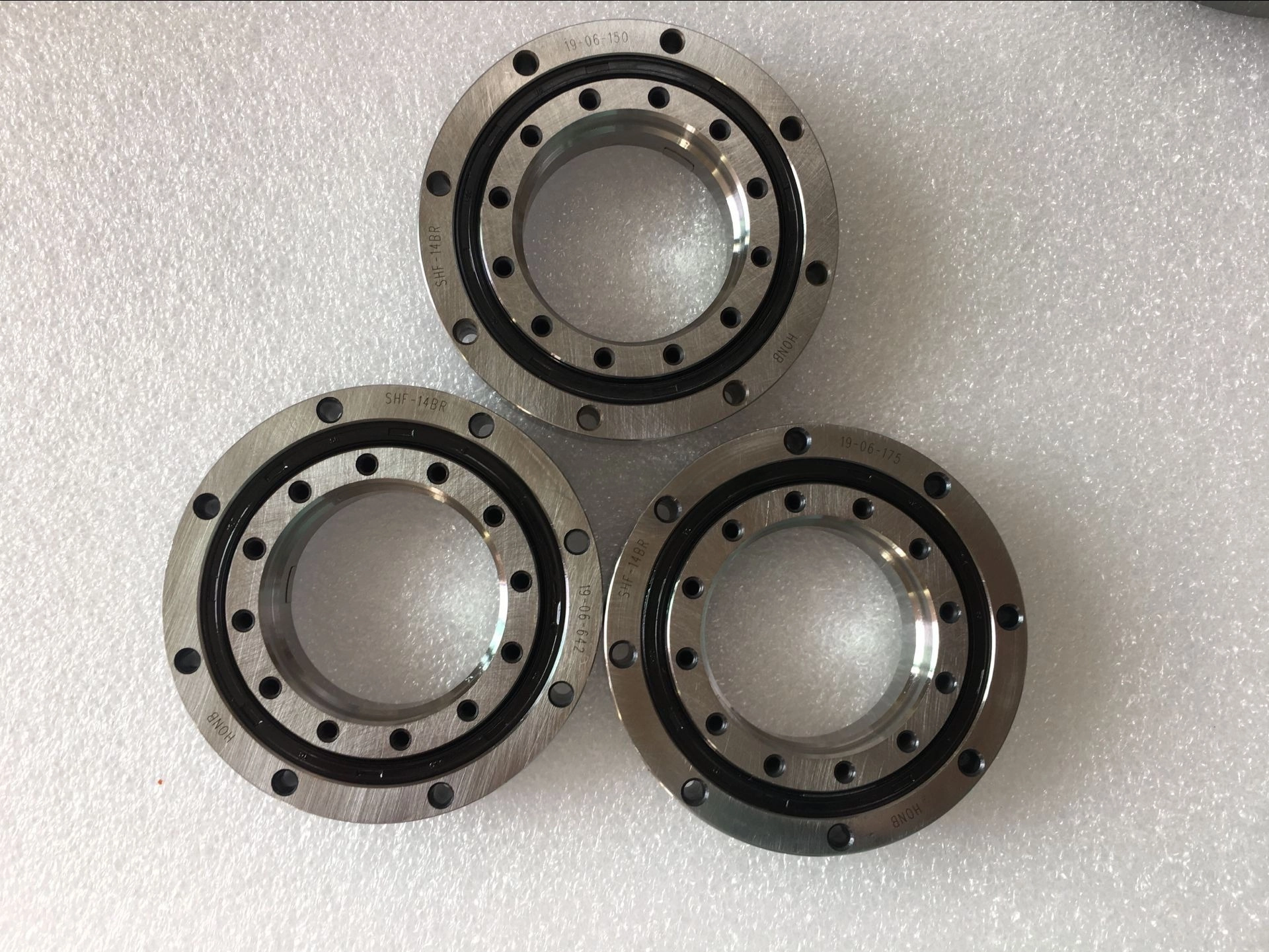

Detailed Images

DETAILS OF SHG/SHF HARMONIC REDUCER

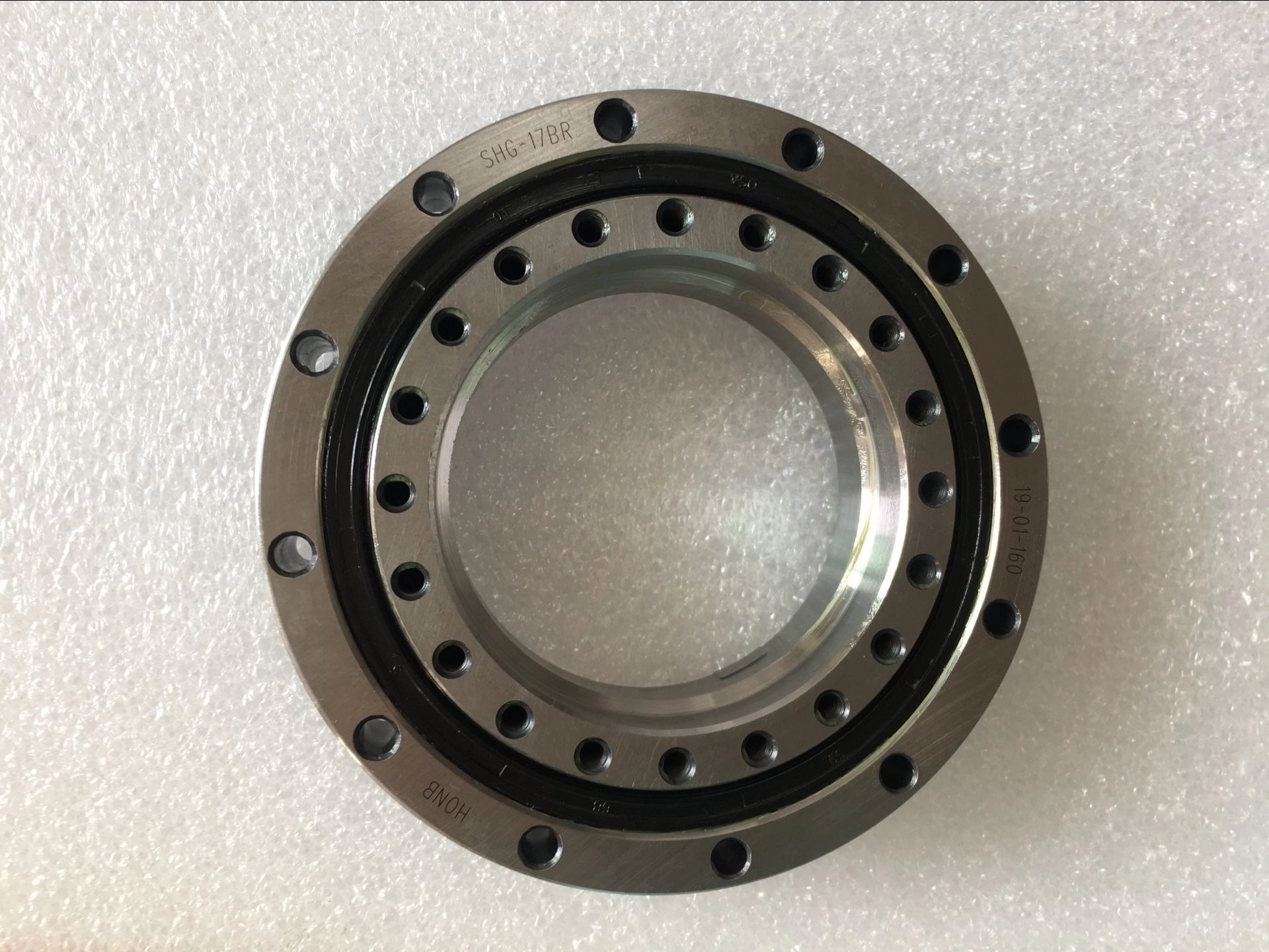

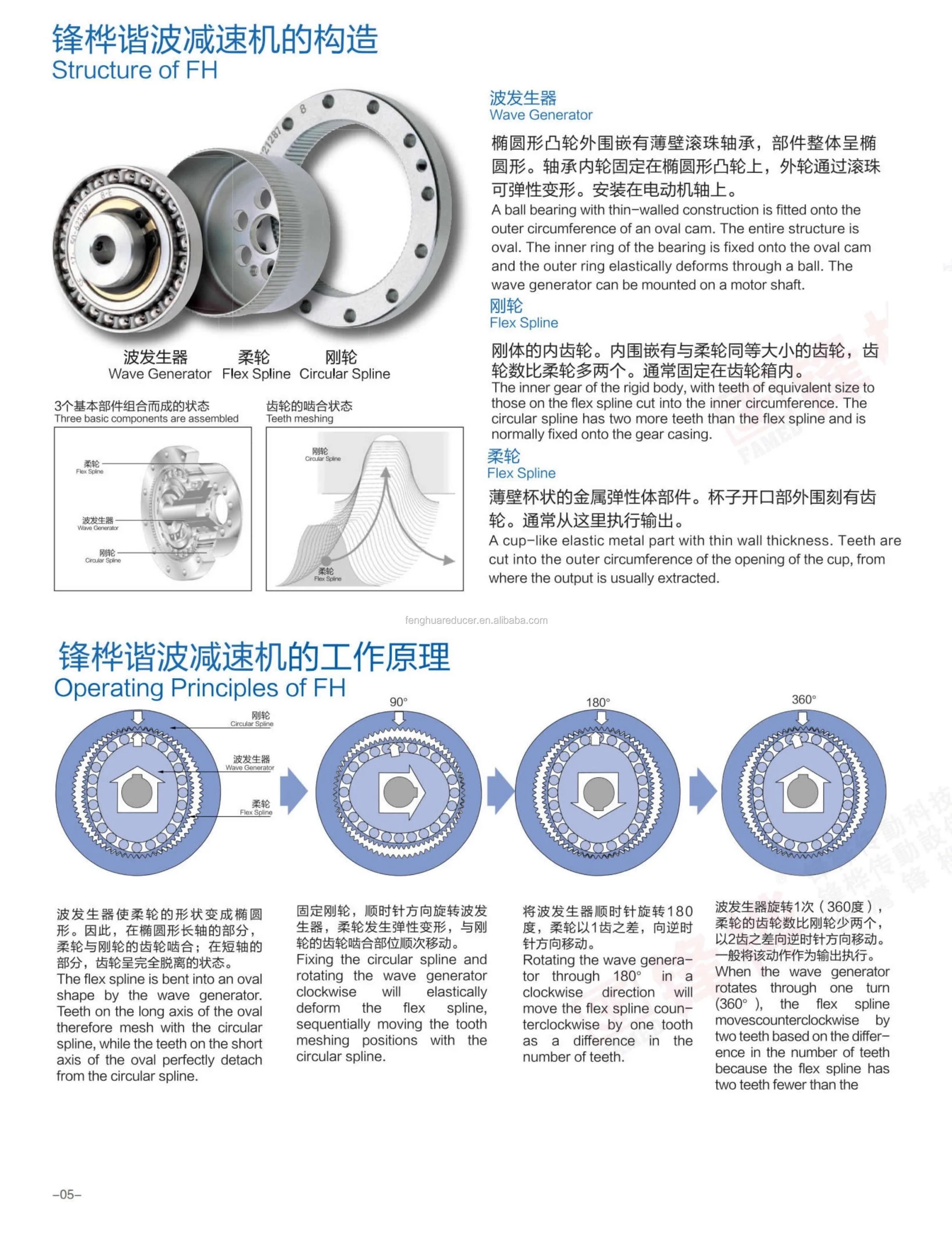

1.The wave generator is installed in the shaft of motor. A ball bearing with thin-walled construction is fitted onto the outer periphery of the oval cam. The entire structure is oval. The inner ring of the bearing is fixed onto the voal cam and the outer ring elastically deforms through a ball.

2.The circular spline is the inner gear of the rigid body which is equipped with the gear with the size of the flexspline, and the number of gears is more than that of the flexspline. It is usually fixed in a gear box.

3.The flexspline is a cup-like elastic metal part with thin wall thickness. Teeth are cut into the outer periphery of the opening of the cup.

4.The flexsplinebears a large alternating load and the requirements for the fatigue strength, processing and heat treatment of the material of the flexspline are relatively high.

5.In the process of harmonic transmission, the meshing of tooth and tooth is surface contact, and the number of meshing teeth (overlap coefficient) is much more, so the load of per unit area is small and the bearing capacity is higher than that of other transmission forms.

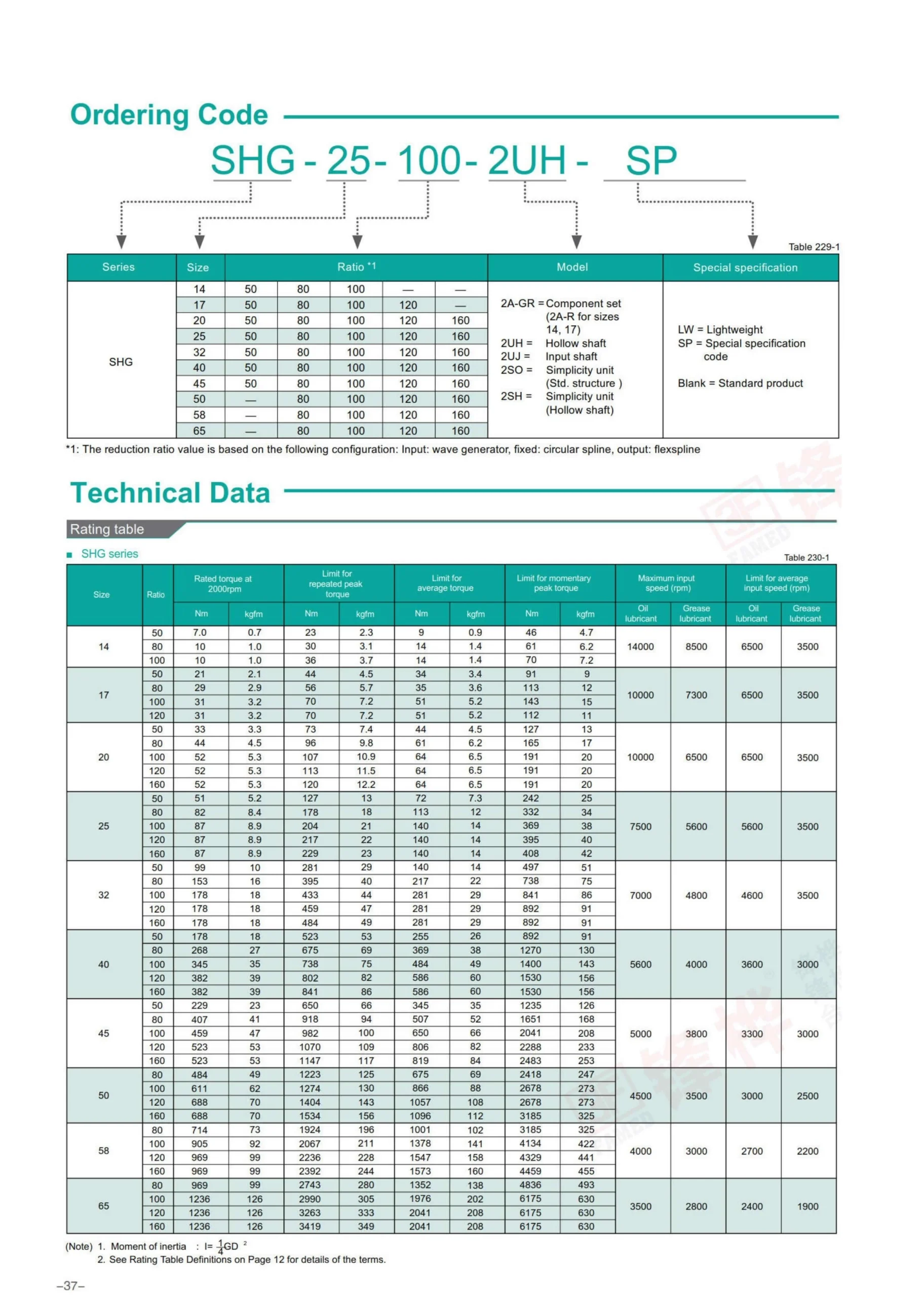

Paramenters

APPLICATION OF HARMONIC DRIVE GEARBOX

The SHG/SHF series harmonic drive gearbox are widely used in fields of robot, metal working machine, processing machine, printing, bookbinding and paper, semiconductor manufacturing systems, measurement, analytical and test systems, medical equipment, optical machine, wood, light metal and plastic machine tool, paper-making machine, crating and packaging machines, flat panel display manufacturing system, communication equipment, printed circuit board manufacturing machine, humanoid robot, telescope, energy, space equipment, aircraft, glass and ceramic manufacturing system, etc.

Key attributes

Industry-specific attributes

Gearing Arrangement Harmonic

Output Torque rated 14~1236Nm

Input Speed 2000rpm

Output Speed depends

Other attributes

Applicable Industries Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Restaurant, Retail, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, robot

Product name Harmonic Gearbox

Heat treatment Yes

Certificate CE; ISO

Input Form Hollow

Quality 1 year Guaranteed

Color Blue or White

Packaging and delivery

Packaging Details Wooden or carton

Selling Units: Single item

Single package size: 23X26X28 cm

Single gross weight: 10.000 kg

Supply Ability

Supply Ability 10000 Piece/Pieces per Month

Related products

-

250W Z55D250-24/90/220 and Z6D250-24/90/220 Micro DC Motor 24V 90V 220V

6W-250W Micro Gear Motor -

200W Electric Motor Three Phase Vertical Installation Small AC Gear Motor With 220V Or 380V

0.1KW-0.37KW Small Gear Motor -

Hollow shaft flange mounted Planetary Gearbox Reduction Gear PAD series

Flange Output Planetary Gearbox