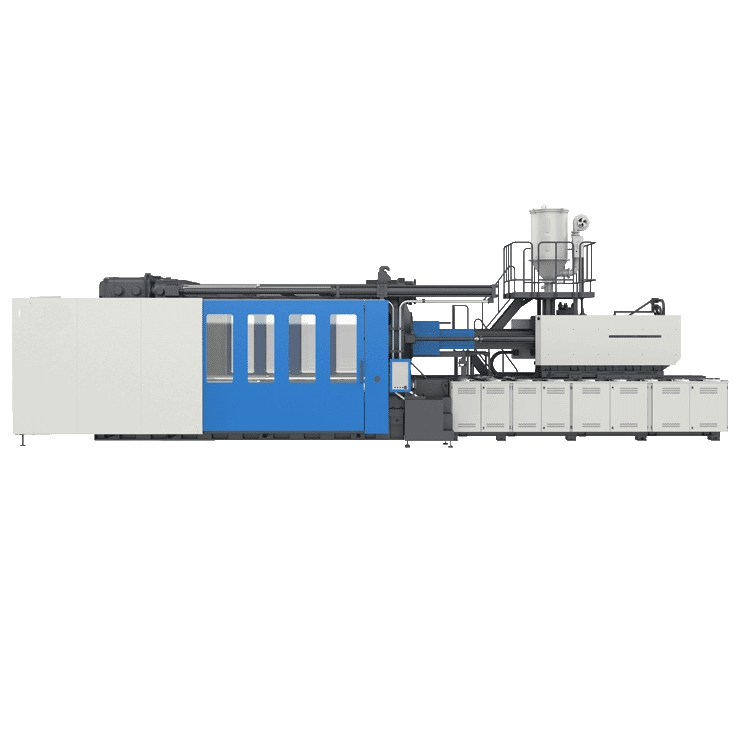

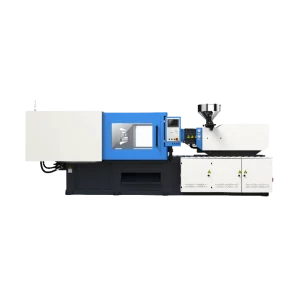

Direct Press Type Injection Molding Machine(130T-2800T)

Direct Press Type Injection Molding Machines are divided into two series: small and medium and large. Both series feature standardized clamping and injection platforms. The design adopts a two-plate direct pressure center clamping structure to provide the maximum mold opening stroke. This configuration meets the production requirements for large-format, deep-cavity products and is suitable for automatic part-picking applications.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

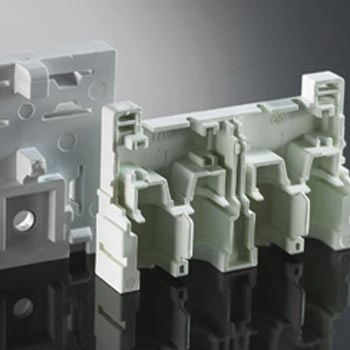

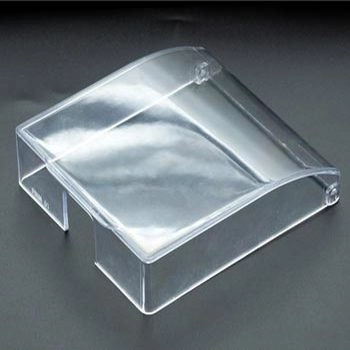

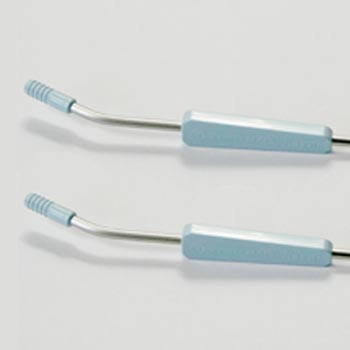

Case & Application

Characteristics

- Small Direct Press Injection Molding Machine(130T-320T)

- 1. Central direct press clamping structure: Small platen deformation, parallel pressure on the mold, high molding accuracy.

- 2. Double-cylinder for injection, linear guide for moving: Stable injection, sensitive action, high precision.

- 3. Patented sealing ring structure: High sealing reliability and long service life.

- 4. Full series of servo drives: CNC back pressure, KEBA controller.

- Medium and Large Direct Press Injection Molding Machine(550T-2800T)

- 1. Multi-cylinder direct press clamping structure: small platen deformation, parallel pressure on the mold, high molding accuracy.

- 2. Double-cylinder/Four cylinders for injection, a linear guide for moving: stable injection, sensitive action, high precision.

- 3. Patented sealing ring structure: high sealing reliability and long service life.

- 4. Large template spacing, high rigid template: suitable for deep cavity injection molding, product thickness is uniform.

Application Industries

- 3C, Home Appliances, Photoelectric, Auto Parts, Daily Chemicals

Small direct pressure injection molding machine (130T-320T)

The small direct pressure injection molding machine features a central direct-pressure mold locking structure, significantly enhancing mold closing force and overall stability. This innovative design ensures a more stable mold opening and closing process during injection molding, effectively minimizing vibration and noise. Additionally, the machine is equipped with a dual-cylinder injection system, delivering precise and stable control over the injection process. The independent dual-cylinder configuration meets the demands of high-speed and high-precision injection, ensuring consistent product quality. Utilizing linear guide movement enhances the smoothness and stability of mold opening and closing. Unlike traditional slider guides, linear guides reduce friction and energy loss, contributing to an extended machine service life.

Medium and large direct pressure injection molding machine (550T-2800T)

In contrast to smaller counterparts, medium and large direct pressure injection molding machines feature a multi-cylinder direct-pressure mold locking structure, delivering enhanced mold closing force and stability. This structural design ensures a stable mold opening and closing process during injection molding, effectively minimizing vibration and noise and accommodating the requirements of larger molds. Additionally, these machines offer optional dual-cylinder or four-cylinder injection systems, providing heightened flexibility and precise injection control. Whether equipped with a dual-cylinder or four-cylinder system, they can achieve high-speed and high-precision injection, ensuring consistent product quality. Topstar holds a patent for the sealing ring structure, effectively preventing lubricant oil leakage and providing more reliable sealing performance. This innovative sealing ring structure reduces lubricant usage, lowers maintenance costs, and minimizes environmental impact.

Related products

-

Servo Motor Injection Molding Machine(90Ton-4000Ton)

Injection Molding Machine -

PET Series Injection Molding Machine(170T-470T)

Injection Molding Machine -

Servo-Driven Injection Molding Machine(90T-470T)

Injection Molding Machine -

All Electric Injection Molding Machine(90T-460T)

Injection Molding Machine