Aluminium Foil Fiberglass Fabric

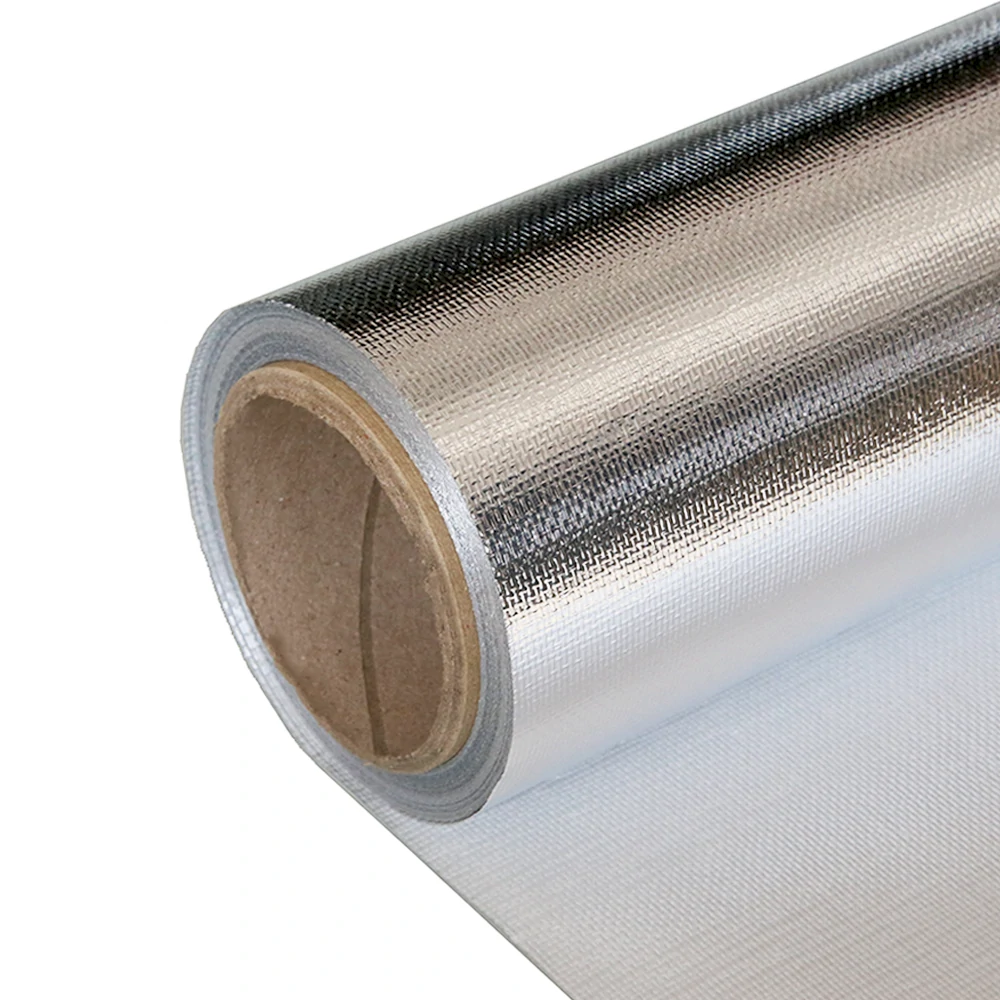

Eleclifeoem provides a variety of glass fiber reinforced aluminum foil fabrics, which use lamination technology and international brand hot melt adhesives to provide thermal radiation reflection protection and thermal management.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

– Performance Parameters –

| Material | Aluminum Foil + Glass Fiber | Test Method | |

| Temperature Resistance | 550°c (Glass Fiber) 150°c (Aluminum Foil) | ASTM-D-6413 | |

| Weight | 460 ± 20 g/㎡ (13.5 ± 0.59 oz/sq yd) | ASTM-D-3776 | |

| Thickness | 0.40 ± 0.03 mm (0.04 ± 0.0012 inch) | ASTM-D-1777 | |

| Color | Silver | – |

| Model | Basic cloth | Thickness of Alu. foil | Overall Thickness | Weight | Width | ||||

| Metric (μm) | US(mil) | Metric (mm) | US(Inches) | Metric (g/m²) | US(oz/sy) | Metric (m) | US(yd) | ||

| HKALB2822 | 7628 | 9,18 | 0.35,0.71 | 0.22 | 0.0088 | 220 | 6.6 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB3242 | 3732 | 9,18,25 | 0.35,0.71,0.98 | 0.42 | 0.0168 | 450 | 13.5 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB6665 | 666 | 18,25 | 0.71,0.98 | 0.65 | 0.026 | 700 | 21 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB6065 | FW600 | 18,25 | 0.71,0.98 | 0.65 | 0.026 | 650 | 19.5 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB8075 | FW800 | 18,25 | 0.71,0.98 | 0.75 | 0.03 | 850 | 25.5 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB2575 | 2025 | 18,25 | 0.71,0.98 | 0.75 | 0.03 | 650 | 19.5 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB8085 | HT800 | 18,25 | 0.71,0.98 | 0.85 | 0.034 | 850 | 25.5 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB3015 | M30 | 18,25 | 0.71,0.98 | 1.5 | 0.06 | 1080 | 32.4 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| HKALB10530 | FG105T 0.8mm | 18,25 | 0.71,0.98 | 0.8 | 0.032 | 600 | 18 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft |

| FG105T 1.0mm | 18,25 | 0.71,0.98 | 1 | 0.04 | 800 | 24 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft | |

| FG105T 1.5mm | 18,25 | 0.71,0.98 | 1.5 | 0.06 | 1000 | 30 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft | |

| FG105T 2.0mm | 18,25 | 0.71,0.98 | 2 | 0.08 | 1300 | 39 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft | |

| FG105T 3.0mm | 18,25 | 0.71,0.98 | 3 | 0.12 | 1800 | 54 | 1,1.5 | 1yd 0.3ft,1yd 1.9ft | |

| Thermal Radiation Reflection | ISO 6942(ISO 11612) | C3 |

| Heat Convection | ISO 9151(ISO 11612) | B1 |

| Flame Spread Coefficient | EN ISO 6942 | C1 |

| Traction Resistance | EN 13934 | Warp 2200 N Fill 740 N |

| Melted Metal Splashes | ISO 9185 (ISO 11612) | D3 – E3 |

– Aluminium Fabric –

Eleclifeoem Provide aluminum foil fabric with various specifications and processes.Aluminium Foil Heat Reflective Fabric is a fire-resistant insulation heat-reflective material composed of glass fiber fabric and aluminum foil on one side.

Fiberglass fabrics increase the properties of radiant heat resistance after laminated with aluminum foil material. The heat-reflective cloth has a high-temperature resistance of 260°C/500°F (Test Standard: ASTM D-6413). In contrast, the glass fiber base fabric has a temperature resistance of up to 550°C/1000°F (Test Standard: ASTM D-6413). Therefore, the rated temperature of One-sided Aluminium Foil thermal reflective fabric is often between 52 °c (125 °F) and 260 °c (500 °F) in everyday use. (More test standards >>)

Aluminum Foil Fiberglass Fabric is a versatile insulating fabric for various applications requiring protection from high temperatures. The aluminum foil layer is waterproof and fully adaptable to oil and acidic and alkaline liquids. Its primary purpose is to use the heat reflection ability to protect the loss of heat energy transmission and act as a heat insulation layer. Although it has some flame retardant properties, Eleclifeoem does not recommend using aluminum foil fiberglass fabric as a fire blanket or for welding work.

Eleclifeoem’s foil fiberglass fabrics have official certification to EN 13501-1 – Classification according to the fire behavior of building products and building elements – with an A2-s1-d0 classification. And it was tested in Texfire’s in-house laboratory according to UNE-EN ISO 15025 – Test Method for Limited Flame Spread – with an A1-A2 rating. In the radiant heat and convective heat tests, a B1 result was obtained according to ISO 9151 – Determination of heat transfer by exposure to flame.

Aluminum foil reflective glass cloth is used for daily precision apparatus protection, is a safety defender for the manufacture, storage, and transportation of dangerous fuel, and can offer better protection for different kinds of piping systems outside

(Learn about materials that reflect heat >>)

– Features –

- Excellent heat-resistant performance

- Excellent heat-reflective performance

- Excellent anti-radiant heat performance

- Excellent heat insulated performance

- Very high resistance to transient temperature

- Good insulating

- Easy to cut

– Application –

- Pipe protection.

- Motor vehicle, construction, chemical, shipbuilding industry.

- Fire seclusion cover.

- Protective wrapping of chemical equipment such as roof, oil, and steam pipelines.

- solar reflective fabric(sun reflective fabric)

- thermal insulation materials for cooling and heating equipment pipelines

- fire resistant aluminum foil protective clothing

- noise and sound insulation materials in buildings outer sheath of ultra-fine glass wool

- moisture-proof, anti-fog, and anti-corrosion packaging materials for export equipment.

- Heat shield, radiant barrier, tin foil heat transfer, thermal reflective insulation fabric, foam insulation, thermal barrier, packing food bag

– Industry –

- Fire fighting

- Chemical industry

- Package

- Food processing

- Survival

- New energy

Related products

-

Welding Habitat System

Fireproof Products -

PVC Coated Fiberglass Fabric

Heat Resistant Fabric -

Controlled Porosity Breathable PTFE Film

Heat Resistant Fabric -

Mechanical Grade – PTFE Coated Fiberglass Fabric

Heat Resistant Fabric