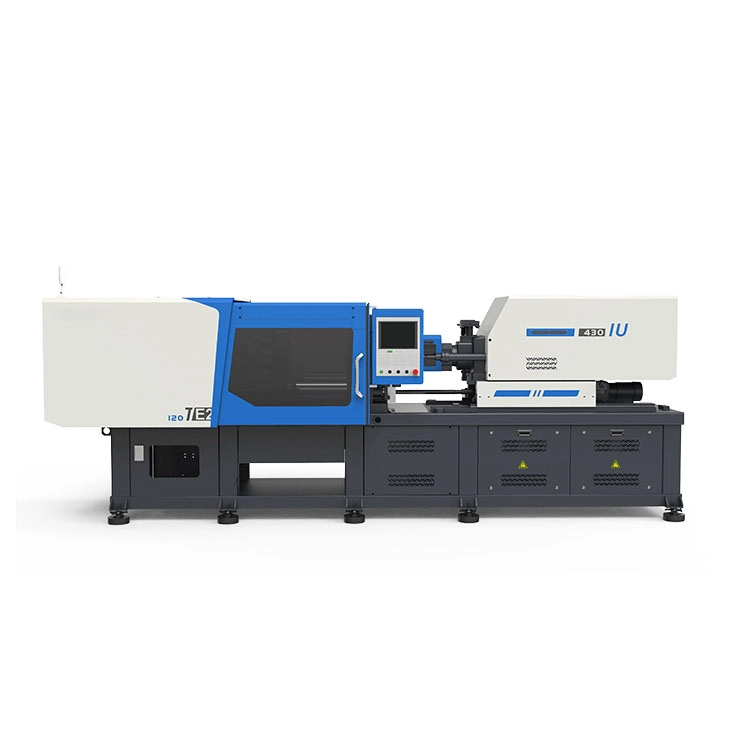

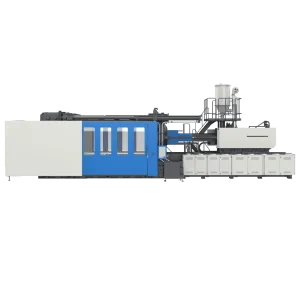

All Electric Injection Molding Machine(90T-460T)

all-electric injection molding machines have all-electric and hybrid share platforms. Their clamping units have high-rigidity templates to stabilize the product and better protect the mold. The popular modulus design can meet the mold installation needs; Optional linear rail support makes movement lighter. The modular design of the injection unit can adapt to various working conditions. Has a humanized interactive interface.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Characteristics

- 1. Low-damping injection unit for precise metering

- 2. The Servo self-driven motor runs at a very low speed and smoothly, and it can eliminate product flow marks.

- 3. High-precision pressure control, with a low-damping injection unit, to improve product stability.

- 4. High rigidity and low friction mechanical structure for precision molding.

- 5. Non-contact tie rod, The tie rod does not need lubrication, reduces pollution, and avoids strain on the column and movie mold linear guide.

Application Industries

- Medical, Home Appliances, Containers, 3C Electronics, Toys, Cosmetics, Auto Parts, FMCG.

More intelligent series all-electric injection molding machine (90T-460T)

The series injection molding machines, representing the new generation, incorporate intelligent electric mold opening and closing technology. This advanced system achieves precise mold actions through an electric drive mechanism, eliminating the need for hydraulic components. This design choice minimizes transmission parts, reduces maintenance costs, and enhances the responsiveness of mold opening and closing actions. The injection process is facilitated by intelligent electro-radiation motion control technology, offering superior precision and reliability compared to traditional hydraulic systems. This technology mitigates issues like leakage and vibration, improving product quality and consistency.

The fully digital bus platform enables swift data transmission and coordination among control units. This digital control approach allows accurate monitoring and control of various parameters in the injection molding process, contributing to enhanced production efficiency and stability. The dynamic multi-level control technology of the system enables real-time adjustments of multiple parameters to meet diverse injection molding process requirements. This flexible control method can be optimized based on the product’s characteristics, ensuring a more precise and stable injection molding process. The series machines can also be equipped with high injection speed, further improving production efficiency and reducing cycle time.

Related products

-

Servo Motor Injection Molding Machine(90Ton-4000Ton)

Injection Molding Machine -

Toggle Hydraulic Injection Molding Machine(90T-650T)

Injection Molding Machine -

Servo-Driven Injection Molding Machine(90T-470T)

Injection Molding Machine -

Direct Press Type Injection Molding Machine(130T-2800T)

Injection Molding Machine