ALUMINUM DIE

CASTING METALS

- Support Customized Products

- Support Single-item Shipment

- Wholesale Price, High Quality

China OEM Factory

If you have needs for custom metal parts, we are a die casting service manufacturer that can help. Since 2004, we’ve held our engineering team and equipment to a high standard to continually deliver strong and durable parts and prototypes. To ensure legendary quality, we operate a strict die casting process that ensures your custom requirements are being met.

Our services include aluminum extrusion and the use of an aluminum welder for precise aluminum welding. We work with extruded aluminum and cast aluminum, and our aluminum plant is equipped to handle various aluminum alloys. We also provide polished aluminum finishes to meet your specifications. Whether you need aluminum extrusions or welding aluminum components, we have the expertise to deliver high-quality results.

What Can We Do?

Aluminum Die Casting Service For Customized Metal Parts And Products With Fast Turnaround Times.

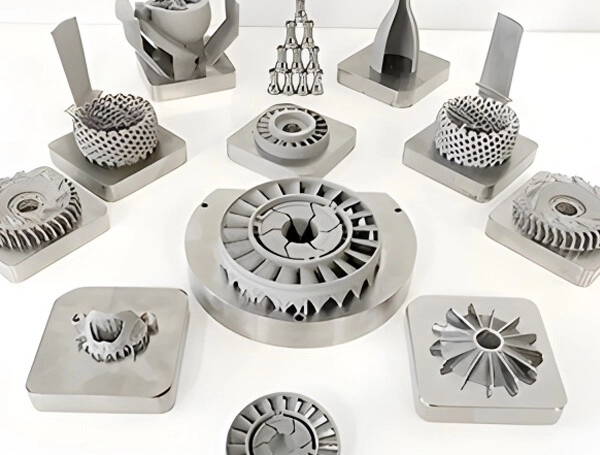

Our Aluminum Die Casting Parts

20+ Years Of Experience On Die Casting

Regarding aluminum products, we can do whatever you want.

Aluminum Product Design

Strong Engineering Support DFM, Mold-Flow&PQ Chart, Mold Design

Strict Quality Control IATF16949, PPAP, Well trained QC team

One-Stop Aluminum Die Casting

We offer die casting services in a variety of materials that produce accurate and complex shapes. Die casting can produce a broad range of parts with perfect finish and astonishing detail. Our dies produce products with a higher tolerance for heat and pressure, that are more durable and last longer than parts made by other methods and are competitively priced.

Professional Quality Control

We work with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom die casting services helps more and more manufacturers bring their ideas to products.

Why Choose ElecLifeOEM as Your Aluminum Die Casting Manufacturer?

1. Experienced

ElecLifeOEM boasts over 20 years of expertise in aluminum die casting, delivering top-notch manufacturing services across various industries.

2. One-Stop Aluminum Die Casting Solution

From mold making to surface treatment, ElecLifeOEM offers comprehensive services. We excel in die casting and collaborate with professional surface treatment partners to ensure high-quality finishes.

3. Master the Core Technology

Mold making is the cornerstone of the die casting process, and ElecLifeOEM shines in this area. Our in-house mold-making capabilities allow us to swiftly address any mold-related issues, ensuring a smooth production process.

4. Strong Production Capacity

With a team of 6 professional engineers, a range of die casting machines from 160 tons to 1100 tons, and over 20 lathes, milling machines, and CNC machines, ElecLifeOEM is equipped to handle your aluminum die casting projects efficiently and effectively.

5. Competitive Pricing

We are committed to delivering the best product quality and die casting services within your budget, ensuring excellent value for your investment.

Our Certifications

Our Aluminum Die Casting Services

ElecLifeOEM is a professional aluminum die casting company in China with over 20 years of experience. We offer comprehensive, cost-effective, and efficient one-stop solutions for various aluminum die casting projects, from tooling creation to packaging.

After completing your product design, we provide two methods to quickly evaluate and refine your design:

- 3D Printing: Offers the lowest cost and fastest delivery, suitable for various metals and plastics.

- CNC Machining: Utilizing our lathes, milling machines, CNC machining centers, and skilled operators, we deliver precision parts quickly.

Die casting molds are critical as they determine the shape, tolerances, and internal filling of the part with molten metal. ElecLifeOEM has 22 years of experience in mold manufacturing, our oldest and most refined service. We have an in-house mold shop and have created over 10,000 molds for diverse industries. Our mold design experience is a significant advantage, and we provide free mold modification and maintenance.

As an experienced aluminum die casting manufacturer, we excel in three different aluminum die casting processes:

High Pressure Die Casting (HPDC): Ideal for lightweight, thin-walled, complex shapes, precision, and large volume aluminum castings.

Low Pressure Die Casting (LPDC): Suitable for heavy, thick-walled, simple shapes, and high-strength aluminum castings.

Squeeze Casting: Perfect for complex shapes, precision, high air tightness, and high-strength aluminum castings.

At ElecLifeOEM, we ensure timely delivery and quality by having our own CNC processing workshop, equipped with lathes, milling machines, and CNC centers dedicated to mold making and die casting. With over 12 years of CNC machining experience, we achieve machining accuracy of up to 0.01mm, capable of handling both large mold making and precision parts machining.

Our specialized surface finishing workshop offers grinding, shot blasting, and polishing to meet most surface treatment requirements for aluminum die casting parts. For additional surface treatments, our long-term outsourced partners provide:

Sandblasting

Anodizing

Powder Coating

Electroplating (Chrome Plating)

Electrophoresis

Choose ElecLifeOEM for professional, high-quality aluminum die casting services that meet all your project needs.

Advantages of Aluminum Die Casting

One of the key advantages of aluminum die casting is its ability to produce near-net shape parts rapidly, often in just a few seconds. Although the initial costs of aluminum die casting can be higher, it becomes a faster and more cost-effective solution for large-scale production. This efficiency has made aluminum die casting a highly popular process across various industries. Additionally, our aluminum plant is equipped to handle various aluminum alloys, including extruded aluminum and cast aluminum. We offer services such as aluminum extrusion and provide polished aluminum finishes to meet your specifications. Our skilled aluminum welder team excels in aluminum welding and welding aluminum components. With the capability to produce high-quality aluminum extrusions, we ensure that all your custom requirements are met efficiently and effectively.

Here are some additional benefits of aluminum die casting:

- EXCELLENT SURFACE FINISH

Aluminum die casting delivers parts with a smooth and high-quality surface finish, often minimizing or eliminating the need for further machining or finishing processes. - REDUCED IMPURITIES

The die casting process results in parts with fewer impurities, enhancing the overall strength and durability of the final product. - VERSATILE APPLICATIONS

Aluminum die casting is highly versatile, making it suitable for a wide range of applications across industries such as automotive, aerospace, electronics, and consumer goods. - INTEGRATION OF METAL INSERTS

This process allows for the incorporation of metal inserts within the castings, improving the functionality and structural integrity of the parts.

Aluminum Die Casting Alloys

Die cast aluminum alloys are known for their excellent casting performance, enabling the formation of parts with complex shapes. By selecting high-quality materials, we offer professional aluminum alloy die casting services.

Here are some commonly used die casting aluminum alloys:

- A356

The A356 aluminum alloy is a casting aluminum alloy with excellent overall performance. It has good casting properties and is capable of producing thin-walled and complex-shaped castings. Through heat treatment, A356 can achieve high strength. This alloy is typically used for casting automotive wheels, transmissions, and housing products. - A360

A360 is noted for its excellent pressure resistance and flowability. Its relatively high silicon content provides high corrosion resistance and strength even at elevated temperatures. This alloy is suitable for die-casting cylinder head covers, sensor brackets, cylinder blocks, and other high-performance parts. - A380 (ADC10)

The A380 aluminum alloy is distinguished by its excellent fluidity, air tightness, and resistance to heat cracking. It offers great machining properties and combines excellent casting, mechanical, and thermal properties. A380 is used to cast a variety of products, including motor equipment chassis, engine brackets, gearboxes, furniture components, generators, and hand tools. - A383 (ADC12)

The A383 (ADC12) aluminum alloy is known for its ease of molding and good heat dissipation, making it suitable for thin-walled products. This alloy is commonly used in Japan and China. By adding Cu, Mg, and Mn, the overall performance of ADC12 is enhanced in various aspects, making it a versatile choice for different applications.

These alloys provide a range of benefits, including high strength, corrosion resistance, and excellent castability, making them ideal for various industrial applications.

Real Reviews From Cooperative Customers

Very impressed by their communication manner, they are just like my colleague right beside me whom I can talk to without a time difference, which will help streamline the program development.

Strong engineering support, reviews our design in every detail and helps us eliminate the chance of making mistakes. Thank you EleclifeoemTeam.

They are the key part of our supply chain, good cost performance and reliable. Yancy is the best customer service officer that I ever met, you always can rely on her to organize and track your orders.

Fast Delivery

Strong productivity ensures fast delivery

Best Quality

Production process in line with international standards.

Competitive Price

High-quality production in batches to reduce costs.

Secure Payments

Multiple payment methods: Paypal, T/T, L/C.

Let’s Work Together!

- Fuzhou Liuzhou Machinery Equipment Co., Ltd.

- Unit 701, No. 177-1, Jinda Road, Jianxin Town, Cangshan District, Fuzhou City, Fujian Province, China

- +86 15806004859

- Support@eleclifeoem.com

- +86 15806004859

Send Us A Message

We will contact you as soon as we see the news and wish you a happy life.